Description

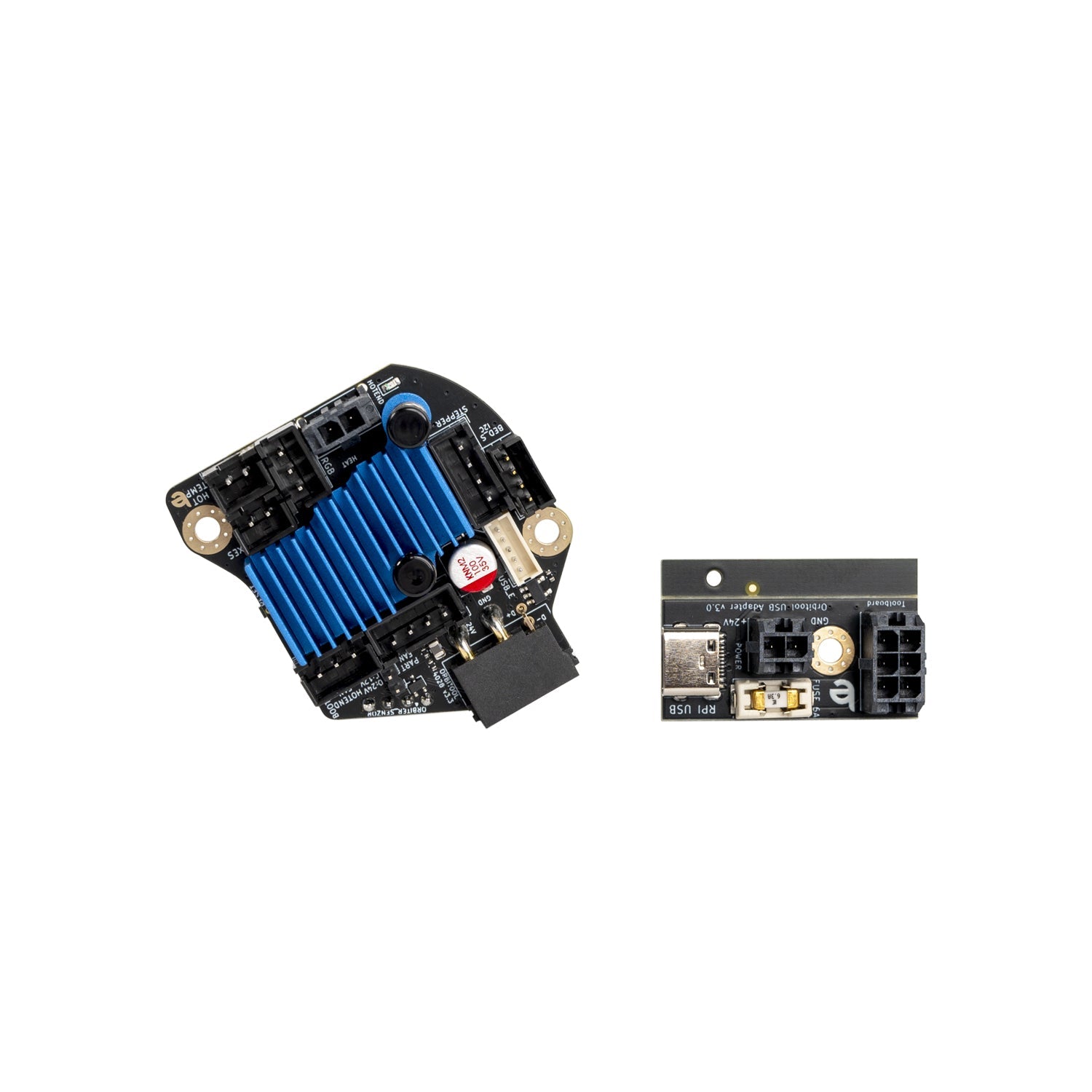

You asked, and it's here! A PCB optimized for Orbiter featuring the orbiter sensor, accelerometer for input shaping, a TMC2209 (TMC2240 for O2S) stepper driver all with USB communication - it's kind of nice.

Should a tool-board magic smoke come out because of user error? Why?

Should a tool-board be destroyed by a fault in your 3D printer? Why?

The answer is NO! And this is what this tool-board is all about!

We are hobbyists, and let’s face it, we do mistakes, and when the magic smoke shows up everybody is disappointed, even if we know it’s a user fault. In this board, I promise you the magic smoke is kept inside extremely tight!

Some of the main features:

• Optimized for Orbiter v2 and SO3 shape and features including orbiter sensor

• STM32F042 microcontroller running on 48MHz

• Automotive USB communication with Raspberry PI

• Onboard LIS2DW12 accelerometer

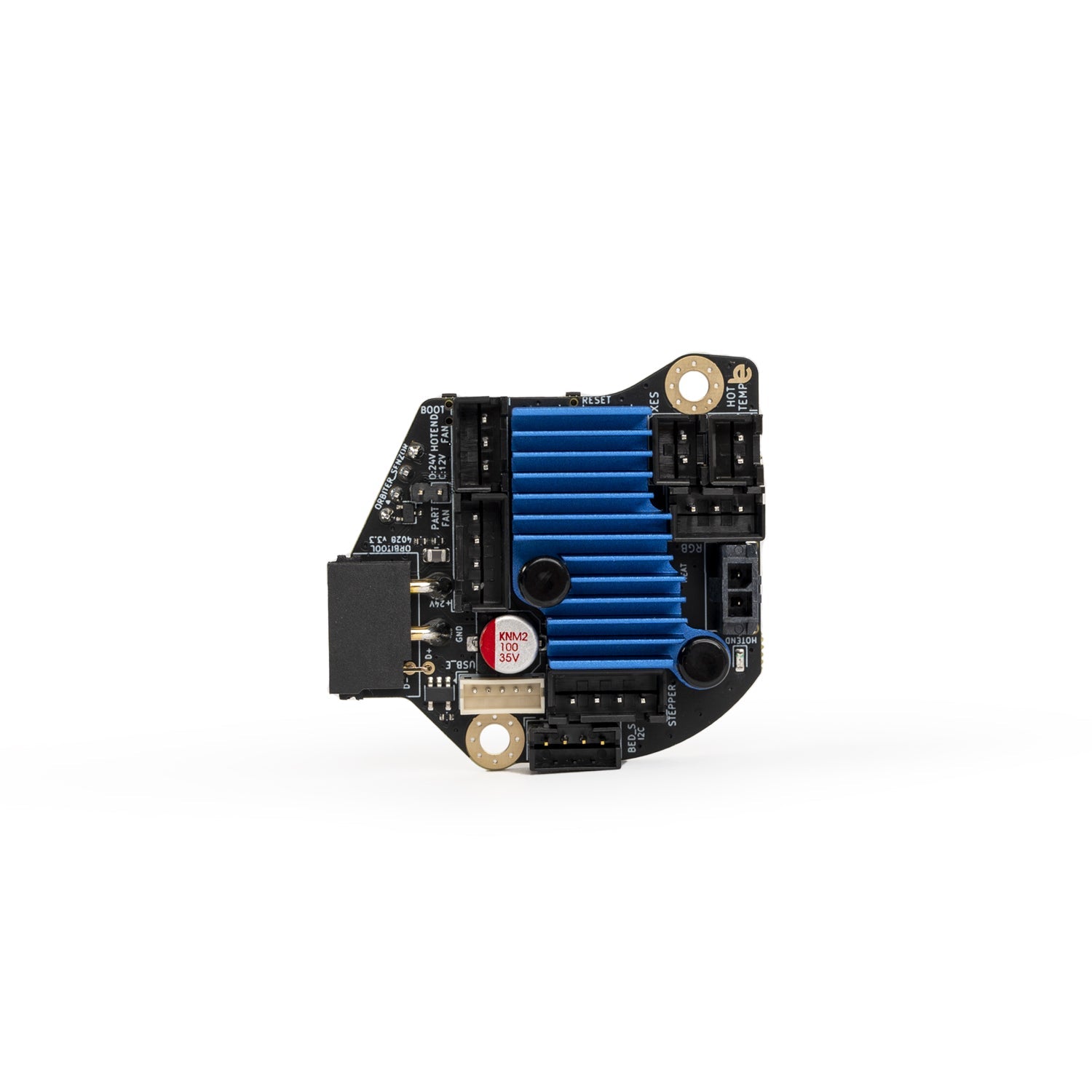

The new O2S for Orbiter 2

This is the second revised version of the Orbiter O2 toolboard.

Some of the main features:

• Optimized for Orbiter v2, v2.5 shape and features, including orbiter sensor

• STM32F072 microcontroller running on 48MHz - full klipper support with automatic update possibility

• Automotive USB communication with Raspberry PI

• One auxiliary USB connector for bed scanner, nozzle camera, or other inteligent USB connected accessory

• Onboard ADXL345 accelerometer

• TMC2240 extruder stepper driver - for better thermal behavior

• Direct connection to Orbiter v2 sensor

• PWM 4,3,2 wire part fan output, compatible with 12/24V fan types with RPM speed input signal

• DC-DC converter based Hot-end fan driver, compatible with 12/24V fan types with RPM speed input signal

• Hot-end temperature sensor input compatible with standard NTC or PT1000 temperature sensor types

• I2C for bed level sensing and scanning

• X-Stop sensor input

• RGB LED driver output

• Onboard temperature sensor

• Advanced thermal management system