Description

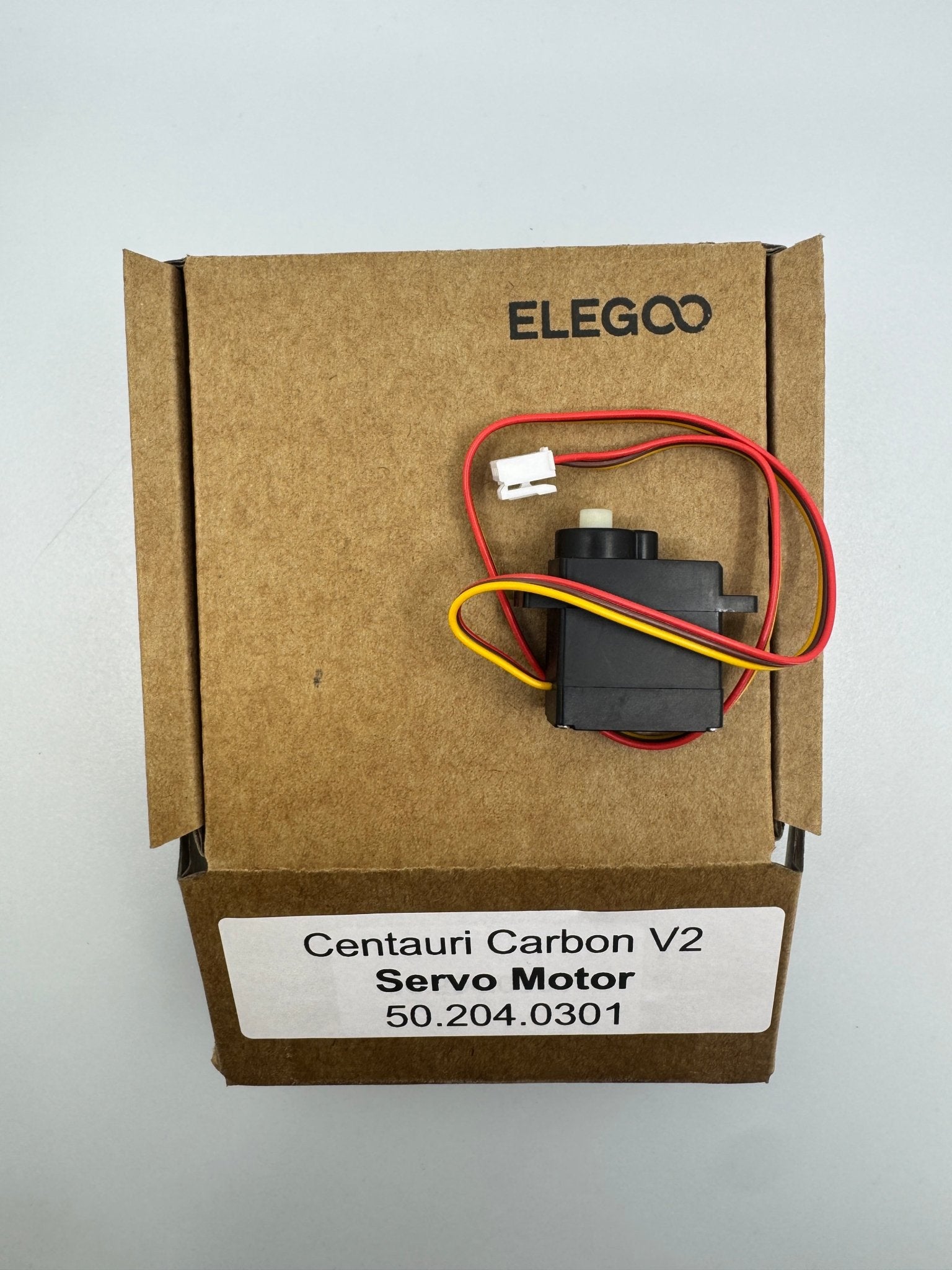

Centauri Carbon 2 Servo Motor 50.204.0301

Unlike the heavy-duty stepper motors that move the print head, this is a small, precision servo used for "auxiliary" mechanical movements. While most printers use the motion of the gantry to "ram" into a lever to cut filament, the Centauri Carbon 2 uses this dedicated servo for more controlled operations.

Core Functions

Automated Filament Cutting: This servo drives the internal blade mechanism that snips the filament during color changes or unloads.

Wiper/Cleaning Mechanism: It is often responsible for deploying the nozzle wiper or adjusting the "tilt" of the cleaning brush to ensure the nozzle is clear of debris before leveling.

Component Deployment: In some sub-models, it acts as the deployment motor for the mechanical bed-leveling probe.

Specs & Details

Type: Micro Servo (similar to an SG90 or MG90S, but with specific Elegoo-proprietary wiring).

Connector: Usually a 3-pin connector that plugs directly into the Extruder Communication PCB (50.204.0297) that we discussed earlier.

Signs of a Failing Servo

If this motor is dying, you will notice:

Chattering or Grinding: You hear a high-pitched buzzing or "jittering" sound coming from the toolhead even when the printer isn't moving.

Stuck Cutter: The filament fails to cut during a color swap, causing the machine to throw a "Cutter Jam" or "Toolhead Timeout" error.

Inconsistent Leveling: If it controls the probe deployment, the probe might fail to drop down, leading to a "Probing Failed" error.

Is your cutter getting stuck during color swaps, or are you hearing a strange "buzzing" sound from the print head? I can help you check if the servo horn (the plastic arm) has simply slipped out of position.