Description

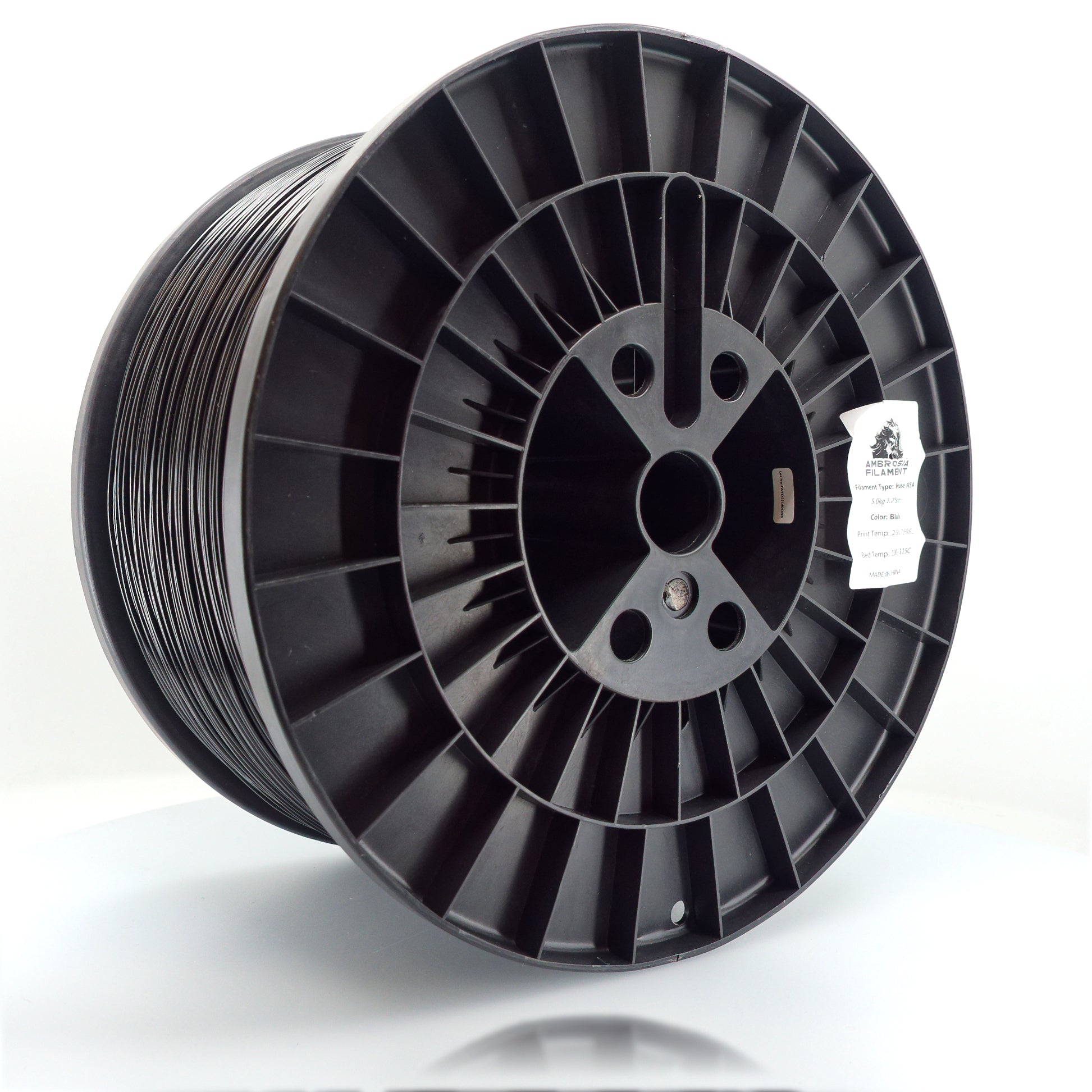

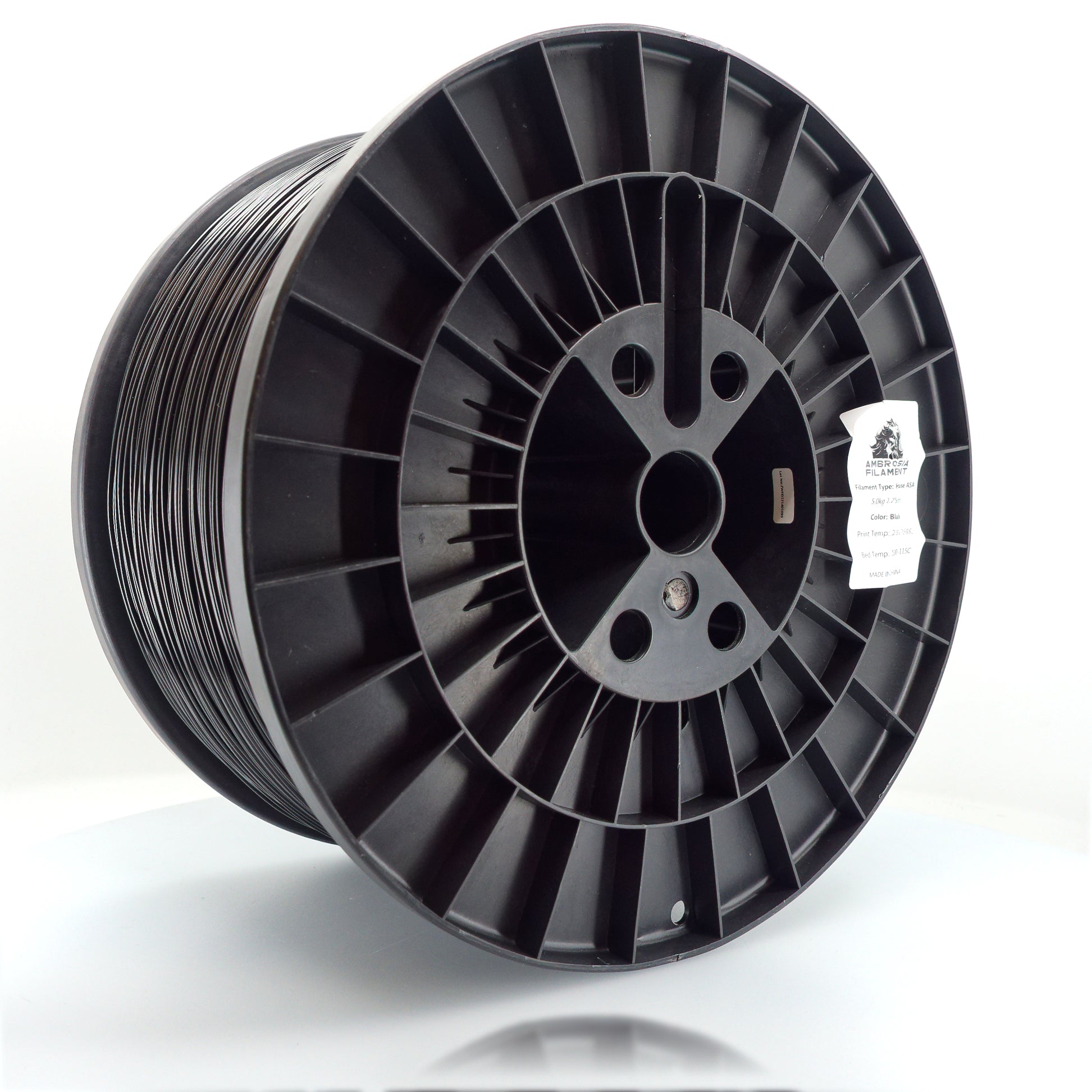

You wanted it larger, here you go! Specifically for our business and high volume printing partners, we have the filament you love in higher capacities. These are made with a plastic spool.

Ambrosia Filament's line of ASA filament is derived from 100% Virgin Grade-A Non-Toxic pellets. Manufactured to a tighter than standard tolerance (+/- 0.03mm) you'll experience consistent extrusion throughout the spool. Free of additives, this filament prints like butter.

Want ASA with a bit of sparkle? We have it here!

Feed your Printer the Filament of the Gods.

ASA is the natural successor to ABS and is great for both mechanical, functional or decorative parts. It prints well, with less warping than some other filaments, however it is highly encouraged to use an enclosure. A heated bed is required.ASA filament has high strength, impact and weather resistance (including UV), and can withstand higher temperatures than many common filaments (e.g. PLA/PETG).

- Arrives to you in a cardboard box, with filament wound in a plastic spool, sealed with a desiccant bag.

- Derived from 100% Virgin (Grade-A) non-toxic pellets

- Diameter: 1.75mm (+/-0.03mm)

- Filament Net Weight: 2KG / 5KG

Check out our other lines of Ambrosia Filament!

| ASA | ASA-CF | ASA Sparkle | ASA Dolos | ABS+ | PETG | PLA |

| PC-ABS | PC-CF | TPU | ABS Matte | ASA-GF | PLA-SILK | |

Ambrosia Filament's Recommended Print Settings for our ASA filament:

| Attribute | Accepted Value(s) [Our Recommended Value] |

| Extruder Temperature | 230-260 Degrees Celsius [250] |

| Heated Bed | 100-115 Degrees Celsius [110] |

| Build Surface | PEI, Buildtak, or similar surface [Textured PEI] |

| Cooling Fan | 0-70% range varies by cooling capabilities |

| Environmental Temperatures | 40-120C [45C] |

| Soluble Support Materials | HIPS |

Technical Specifications for our ASA Filament:

| Physical Properties | Test Methodology | Values |

| Density | ISO1183 | 1.08-1.09 g/cm^3 |

| Melt Flow Rate (250C/2.16KG) | ISO 1133 | 20-25 g/10min |

| Mechanical Properties | Test Methodology | Values |

| Tensile Strength | ISO 527 | 42-45 Mpa |

| Elongation at break | ISO 527 | 9-12% |

| Flexural Modulus | ISO 527 | 1200-1400 Mpa |

| Flexural Strength | ISO 178 | 75-79 Mpa |

| Impact Strength | ISO 180 | 19-20 KJ/m^2 |

| Thermal Dynamic Properties | Test Methodology | Values |

| HDT@ 0.455 MPa(66 psi) | ISO 75 | 88C |

Filament can absorb moisture easily. To prevent moisture absorption and contamination, the packing of filament should be kept sealed and in an airtight container with desiccant.