Beschreibung

Description

PolySonic™ PLA Pro is a tough PLA that can print at incredible speeds. With its advanced formulation, this filament ensures durable, rugged prints, with an impact strength similar to ABS and bending strength outperforming ASA & PETG. When time is of the essence for functional parts, PolySonic™ PLA Pro is the ideal choice for you.

A material is considered "High Speed" if it fulfills the following 3 criteria at a set printing temperature:

1) Flowability: It can extrude consistently at 24mm3/s on popular extrusion system. (equivalent to 300mm/s at 0.2mm layer height with a 0.4mm nozzle)

2) Formability: At 24mm3/s, it maintains similar surface quality, overhang and bridging as printed at lower speed.

3) Functionality: At 24mm3/s, it maintains at least 80% of its overall mechanical properties when printing at lower speed. (mainly: layer adhesion, tensile strength and impact strength)

PolySonic™ PLA at 230˚C

1) Maximum flow*: 24mm3/s** (tested on a customized extrusion platform equipped with an E3D volcano hotend, 0.4mm nozzle with Hemera XS extruder)

2) Confirmed similar quality Polymaker Scientist when printed at 4mm3/s and 24mm3/s

3) Layer Adhesion at 4mm3/s-24mm3/s: 33.6-31.9 MPa (Maintain 95%)

Tensile Strength at 4mm3/s-24mm3/s: 41.2-39.3 (Maintain 95%)

Impact strength at 4mm3/s-24mm3/s: 22.7-19.4 kJ/m2 (Maintain 85%)

* Maximum Flow: Flow at which the measured flow is decreasing below 95% of the requested flow.

**

For 0.2mm layer height with 0.4mm nozzle: 24mm3/s -> 300mm/s

For 0.1mm layer height with 0.4mm nozzle: 24mm3/s -> 600mm/s

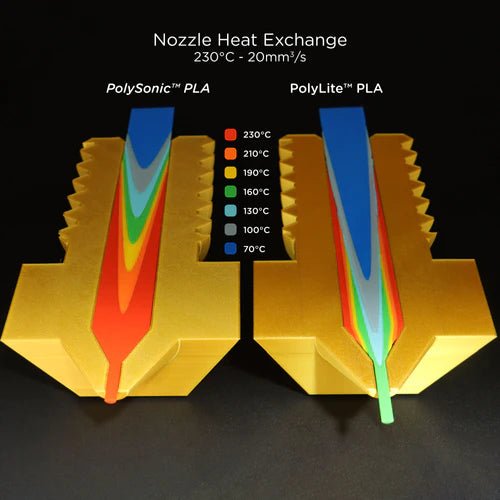

1) Surface Quality at high speed:

When printing at high speed, the nozzle will actually experience a wide variety of speed going from 0mm/s to the max speed set on the slicer. The higher the max speed, the wider the range of different speeds. The issue is with the printing temperature being the same, the extrusion temperature will vary dramatically leaving difference surface finishes on the print (from glossy to matte because of a phenomenon called: Shark Skin), High Speed filament reduces these differences by displaying similar surface finish in a wide range of flow rates.

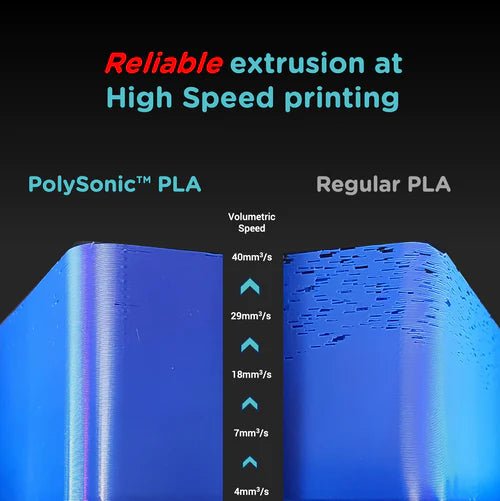

Additionally, high speed filament will extrude much more consistently within the speed range providing a smooth surface whereas regular filament will display holes, artifacts and layers with different thicknesses.

2) Mechanical Properties at high speed:

High Speed filament will display far greater overall mechanical properties when printed at higher speed than regular filament because of the more consistent extrusion and the optimized cooling/melting rate of the polymer.

3) Higher Throughput:

Thanks to 1) and 2), you are able to output the same quality part at a much higher pace from your 3D printer. This advantage is ideal for businesses using 3D printing to produce their products.

Printing Temperature:

Classic: 190˚C - 230˚C

High Speed: 210˚C-230˚C

Printing Speed:

Classic: 50mm/s - 100mm/s

High Speed: 100mm/s - 300mm/s

Bed Temperature: 25˚C - 60˚C

Fan: ON

Direct Drive:

Retraction Distance: 1mm

Retraction Speed: 20mm/s

Indirect Drive:

Retraction Distance: 3mm

Retraction Speed: 40mm/s

Drying Settings: 55˚C for 6h

(Only if the material has absorbed moisture)

1kg cardboard spool:

Spool Inner Hole Diameter: 55±1mm

Spool Diameter: 200±1mm

Spool Width: 65.6±2mm

Spool Weight: 140±7g