Description

From the Orbiter Project:

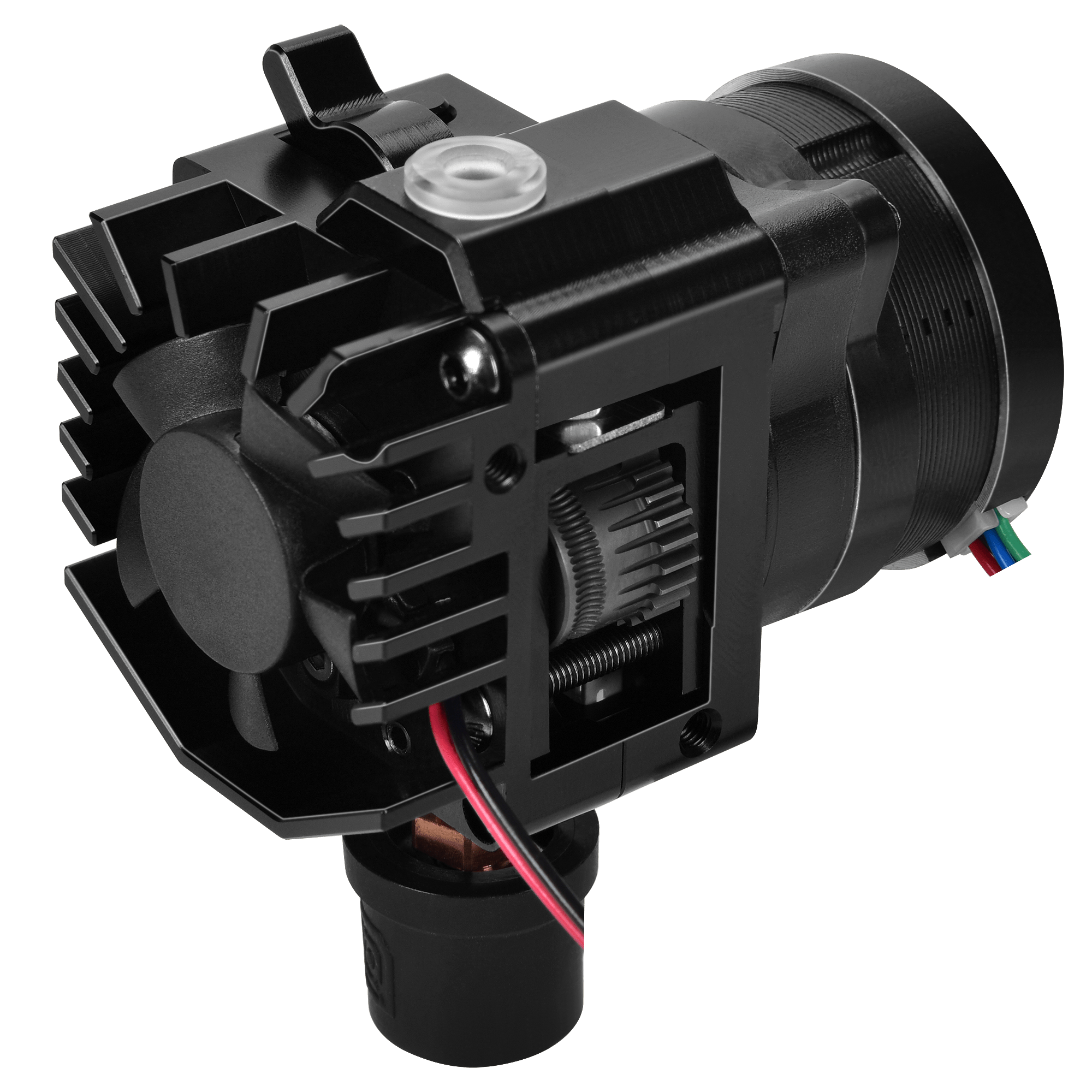

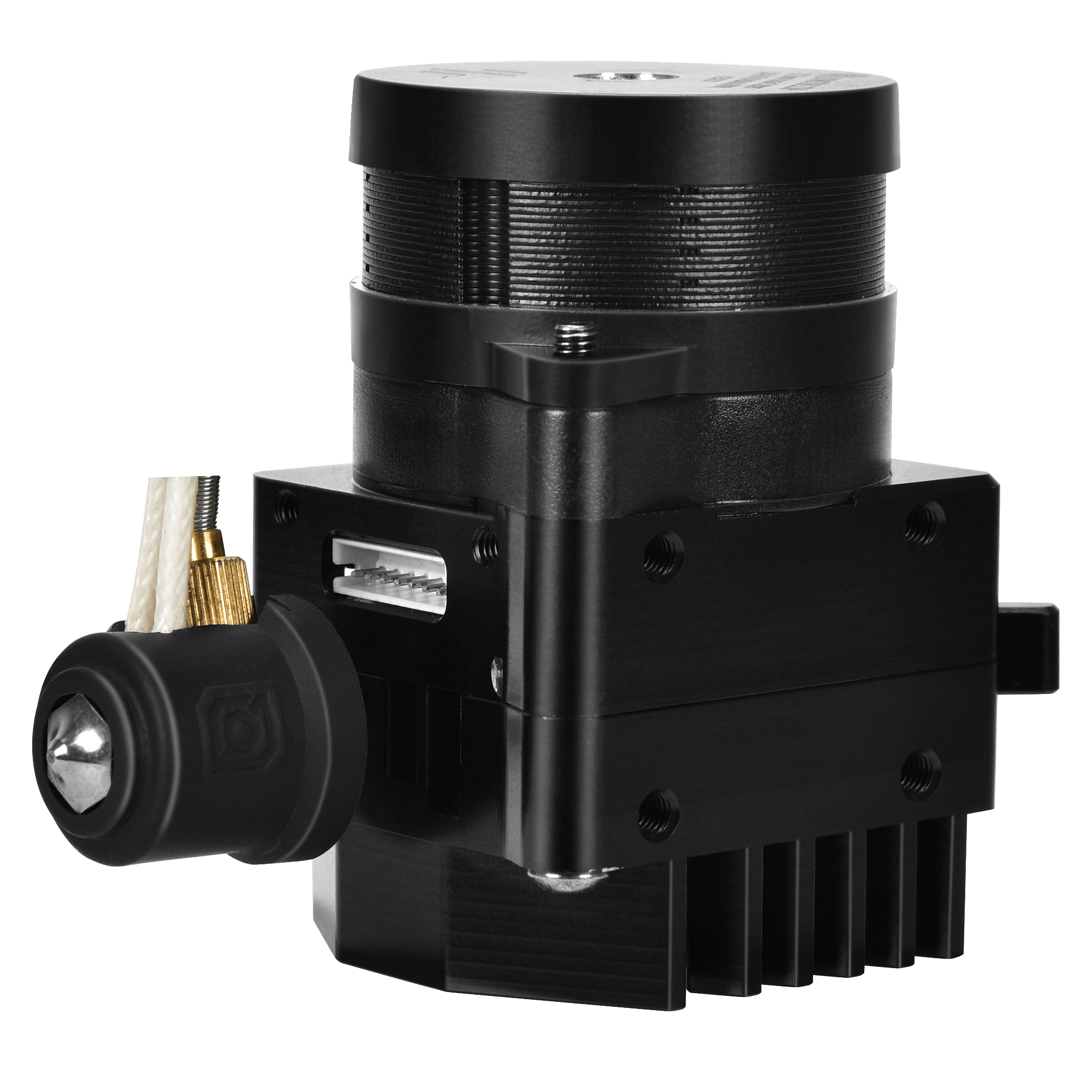

Smart Orbiter v3.0 is a brand new innovative all in one dual drive extruder.

The main mission of this design is the integration o the well proven Orbiter v2 concept into a lightweight all in one smart extruder.

Why smart? This is the first extruder with integrated electronics. Together with Klipper, it is an awesome combination I guarantee!

1. Features And Performance

This brand new all in one extruder design with many cool features we call Smart Orbiter v3.0 is one of my latest and finest extruder design made in collaboration with LDO Motors. The extrusion system concept and mechanical performances are similar to the Orbiter v2.0 but completely redesigned from ground up.

Summary of the coolest features

- Pure plated copper heat-block with 72W ceramic heater and Bondtech CHT nozzle for highest possible weight VS flow ratio;

- Heat-break performance optimized with finite elements analysis for extreme temperature gradient to ensure clogless free printing experience;

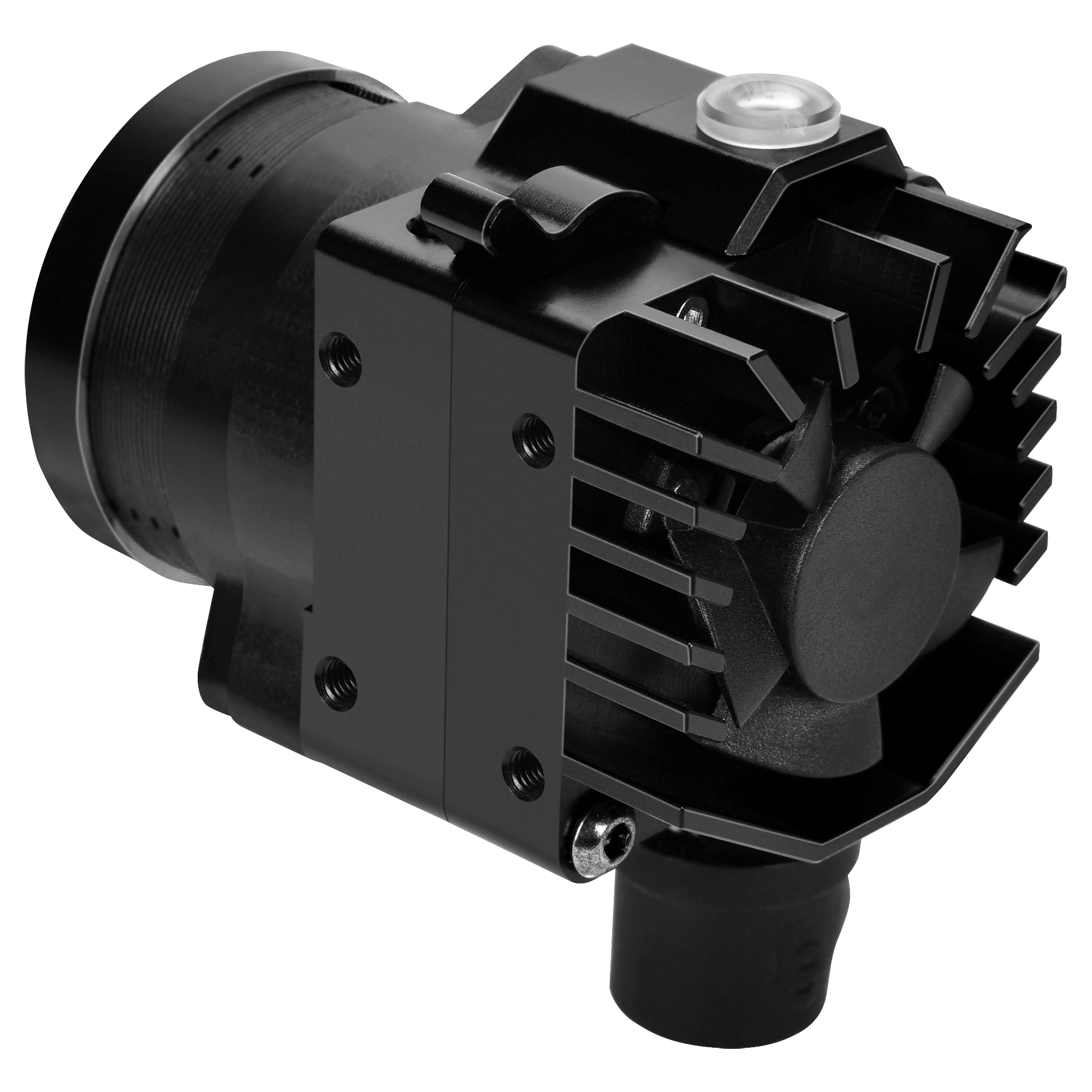

- Unique tensioning mechanism with elastic predefined tension levels

- Frameless recessed fan to reduce the extruder weight and outside dimension

- Large RNC coated dual drive gears with planetary gear reduction, similar to orbiter v2.0

- New precision main shaft design to reduce gear eccentricity

- Full aluminum housing with Delrin plastic gears for low noise and long lifetime

- The smart feature – integrated electronics

- Easy remove system of the secondary drive gear for easy cleaning and maintenance

- Double filament exit guide system for best TPU printing performance

- Overall weight is 175g

Some more information about this great all-in-one extruder/hot end:

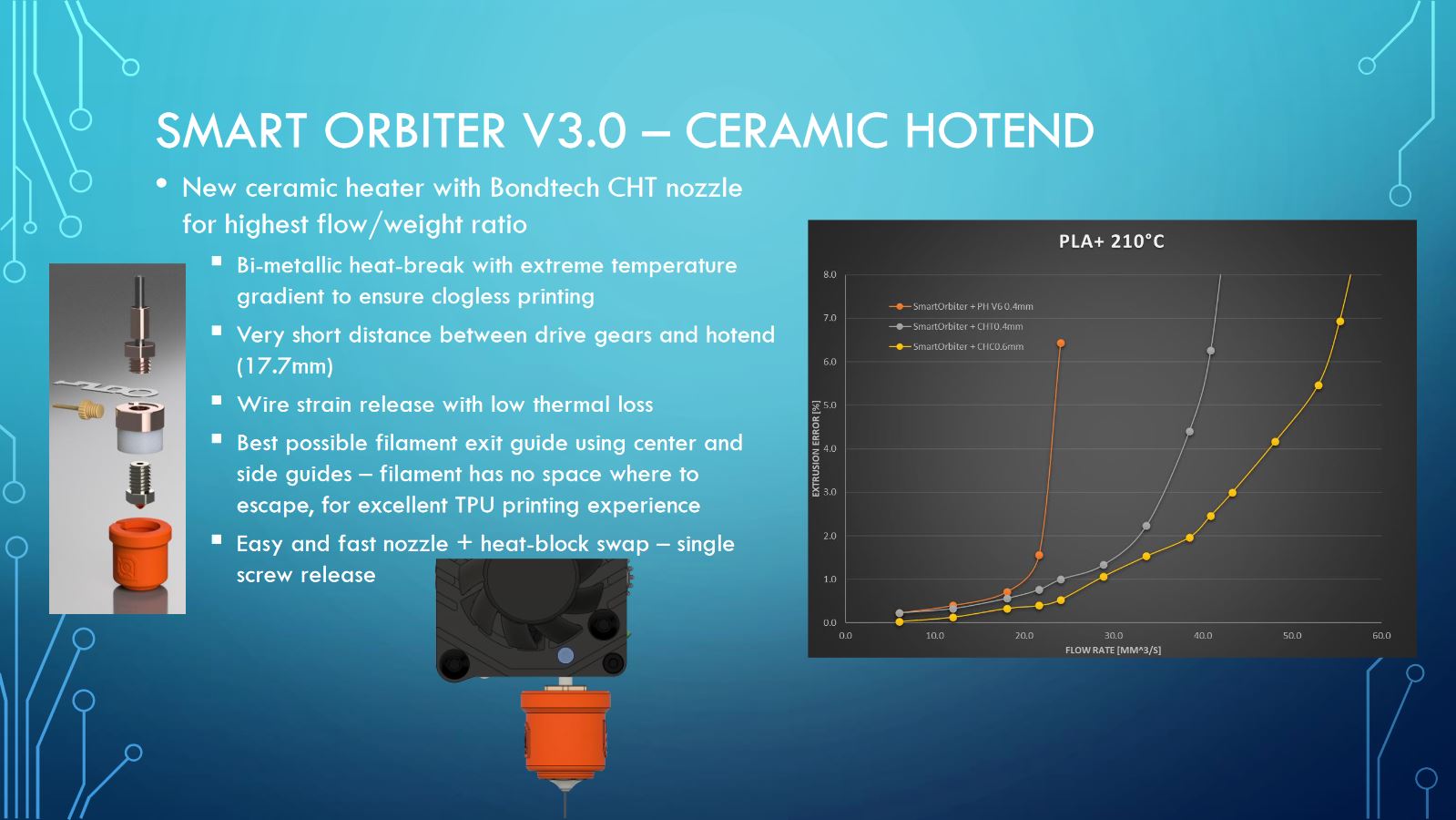

Heat-Block

New 72W ceramic heater with Bondtech CHT nozzle for highest flow/weight ratio.

Very short distance between drive gears and heat-block (17.7mm)

Screw mounted thermistor for best thermal contact (104NT-4-R025H42G - Optional PT1000)

Easy and fast nozzle + heat-block swap – single screw release

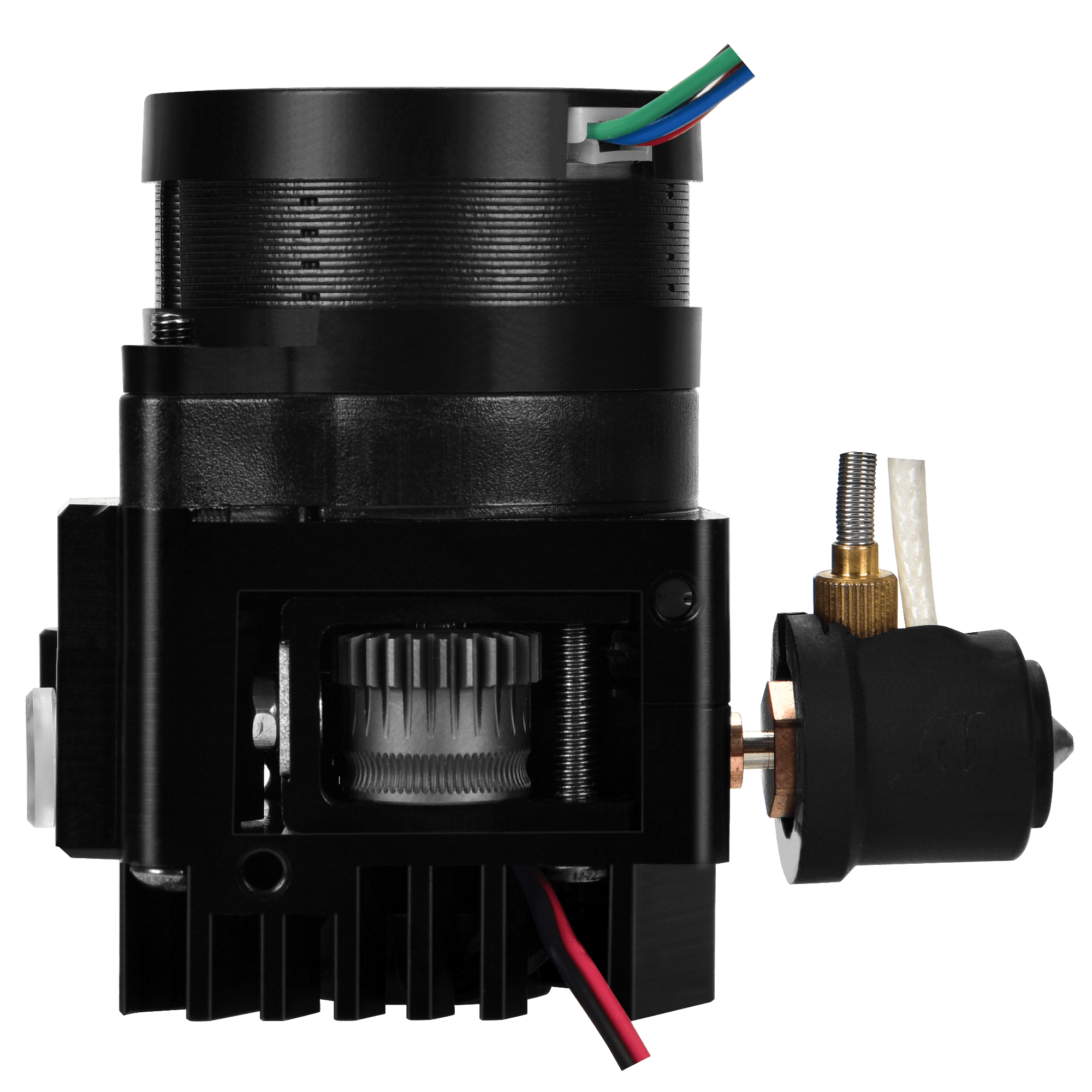

Bimetallic Heat-Break

Heat-break made out of stainless steel tube with 0.25 mm wall thickness for lowest heat transfer.

M7 heat-block mounting screw - compatible with V6 heat-block styles

Bi-metallic heat-break together with the heatsink optimized for highest temperature gradient using finite element analysis.

Wire Strain Release

Stainless steel wire strain release feature to avoid wire brake issues of the heater and thermistor wires.

Shape optimized for bad thermal transfer to reduce thermal losses.

Quick Nozzle Change

Quick nozzle change optimized for best thermal performance implies a simple swapping of the heat-block retained by one single screw.

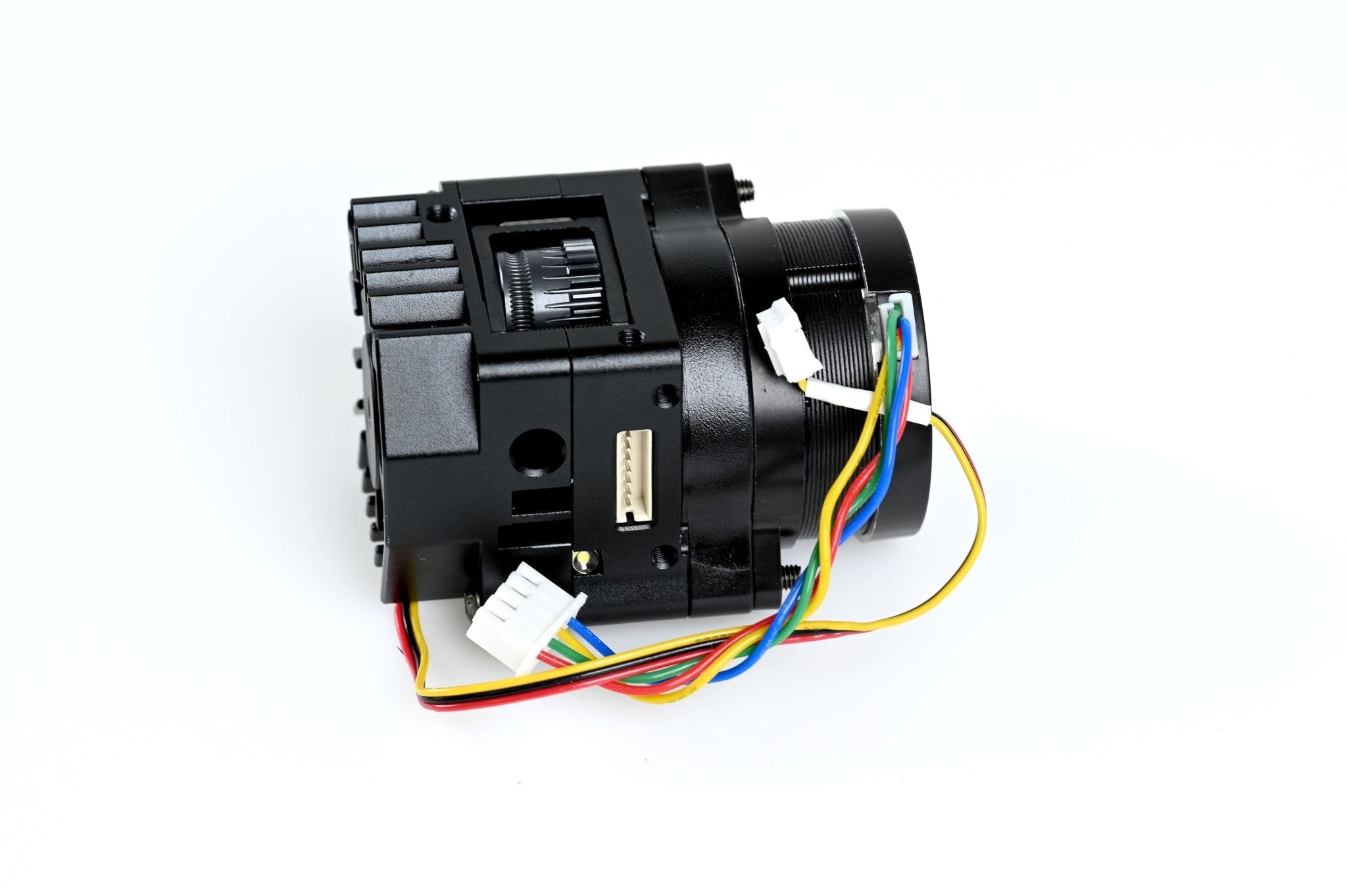

Heater and thermistor wires connected via microfit connectors for easy electrical disconnection.

High Flow

Best optimized weight vs flow ratio thanks to Bondtech CHT nozzle, flow rate 35-40 mm3.

Note: Actual flow depends on the filament type, nozzle temperature and size. The picture exemplifies a typical behavior measured using SUNLU PLA @ 210°C. The figure shows performance results using standard V6 plated copper nozzle, Bondtech CHT 0.4mm and 0.6mm.

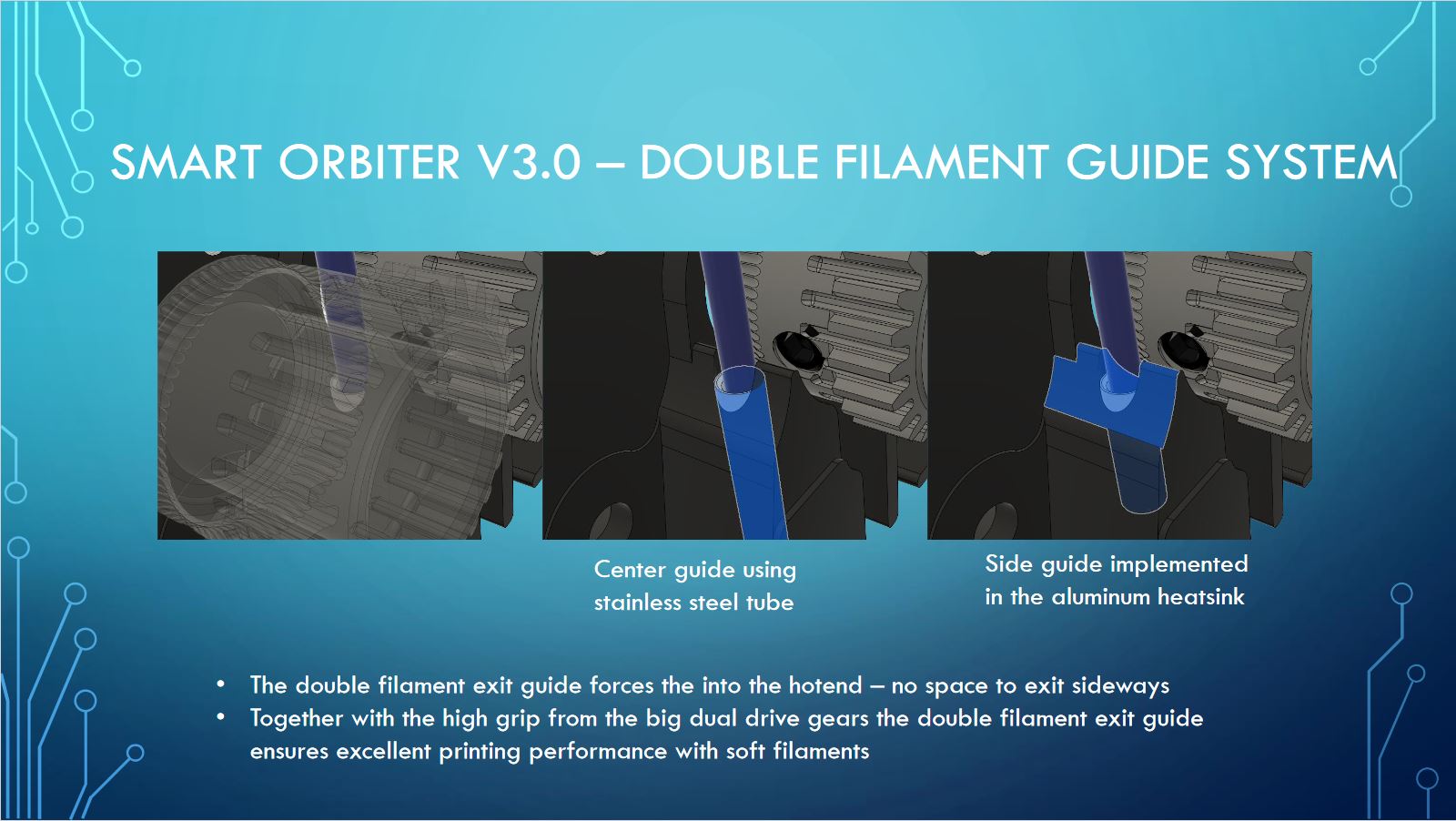

Double Filament Guide

For good TPU printing experience its important that there is no gap left between the drive gears and exit guide where the filament could escape.

The two guarding features, center and side leads to no physical space where even the most flexible filament can escape.

The center guide stops filament to be chewed in between the drive gear tooths.

The side guides stops the filament to be chewed into the gap between the drive gears.

Filament Tensioning

Filament tensioning lever with three predefined positions: open, L1 (soft) and L2 (hard).

No need to guess anymore the correct tensioning, the predefined positions ensure repeatable and always correct tensioning.

The elastic tensioning arm makes sure the tensioning is independent from filament diameter and avoids filament deformation due to over-tensioning.

Secondary Drive Gear

Secondary drive gear easy remove feature for easy cleaning and maintenance.

The secondary drive gear together with the tensioning arm can be removed simply by removing one M3 screw.

Precision Mainshaft

Redesigned octagonal shaped precision aluminum main shaft.

The outer diameter of the shaft is slightly bigger than the inner diameter of the bearing and the main drive gear. The octagonal shape allows slight deformation of the aluminum shaft to match the exact inner diameter of the bearings and the drive gear, therefore reducing any eccentricity to a minimum.

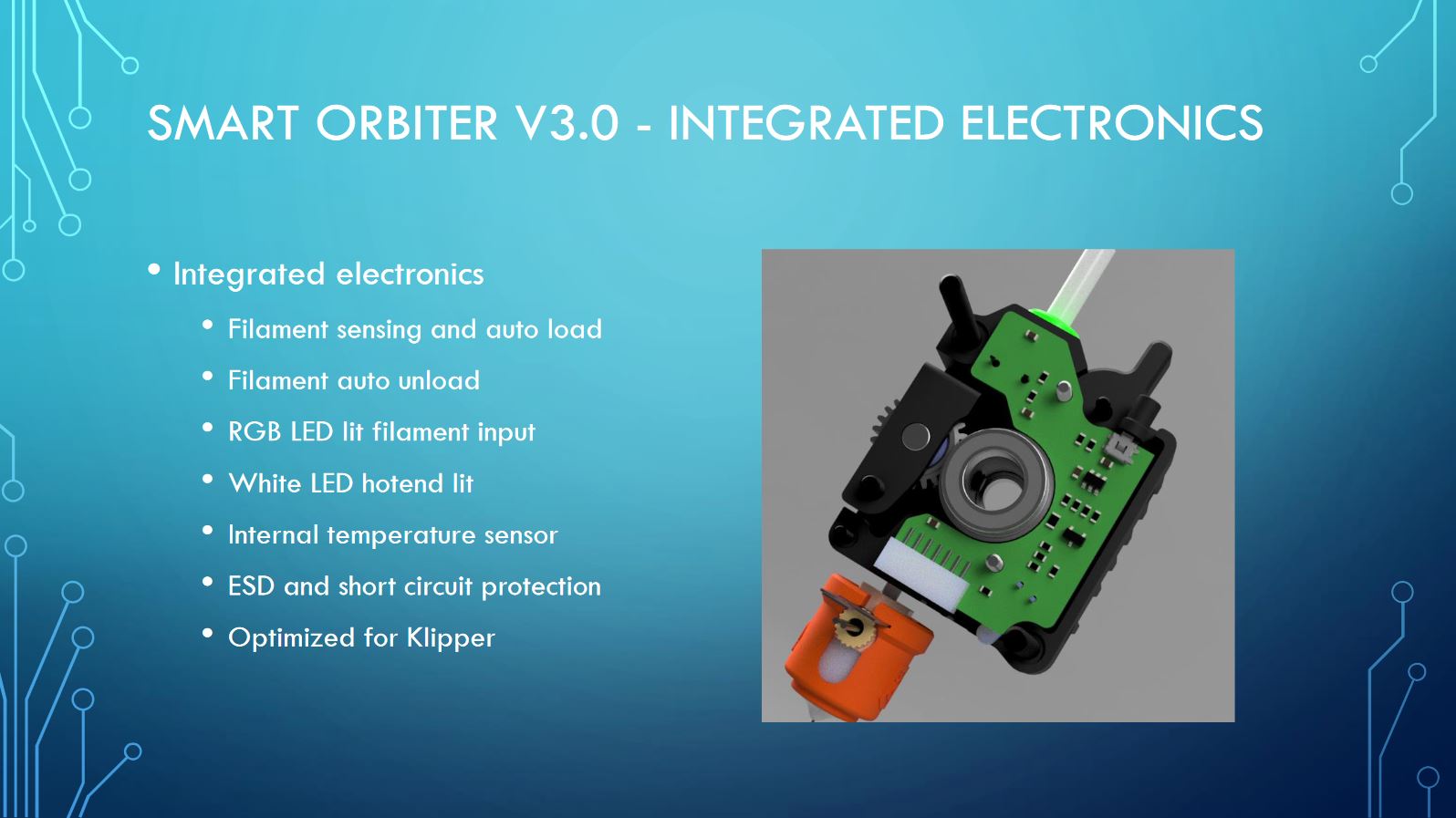

Integrated Electronics

Integrated electronics, the smart features:

-

Filament sensing and auto load

-

Filament auto unload

-

RGB LED lit filament input

-

White LED hotend lit

-

Extruder temperature sensor

-

ESD and short circuit protection

-

Optimized for Klipper

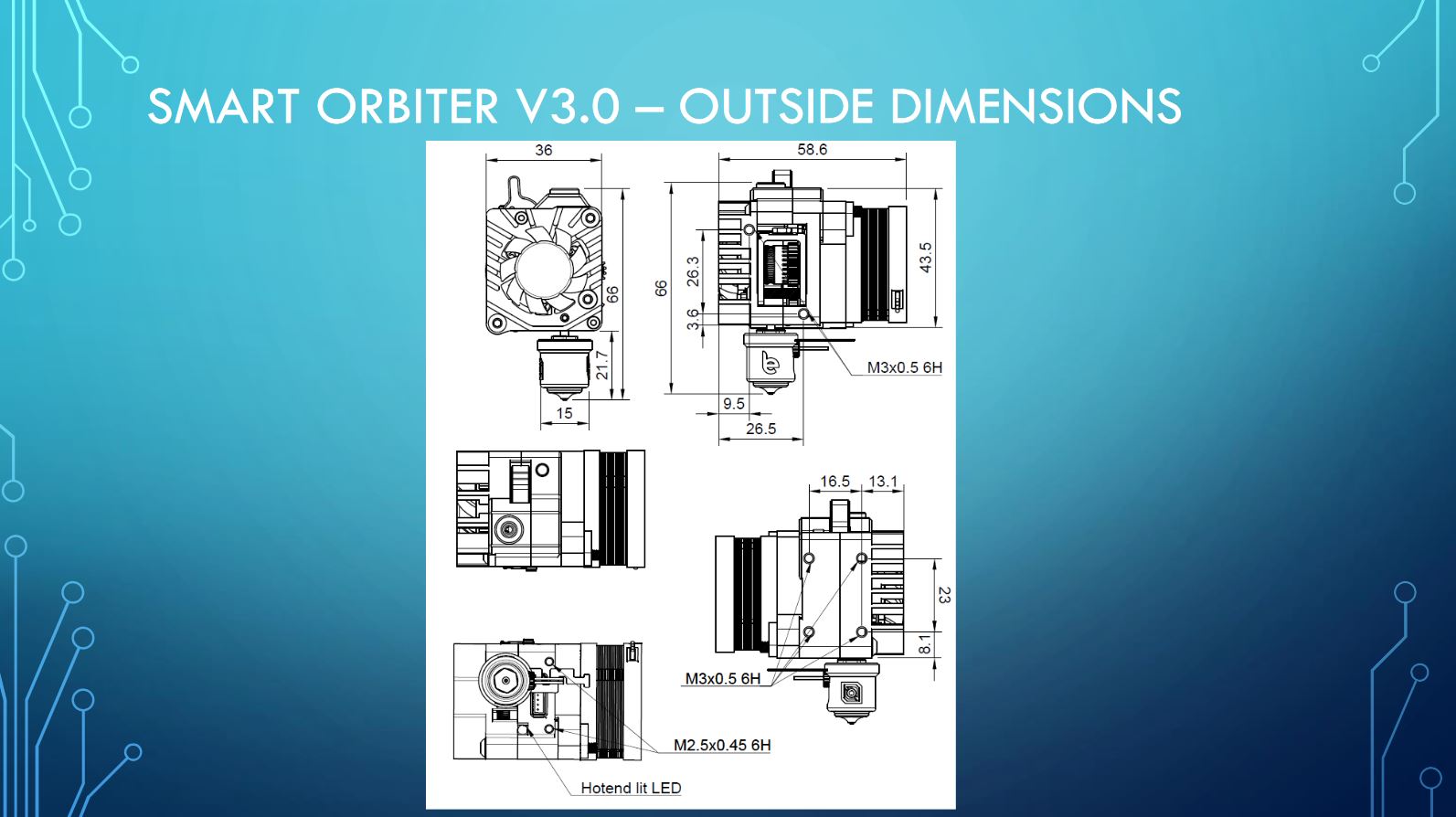

Outside Dimensions

Total weight of 175g.

For more information see the Orbiter Project page