Description

Want to add a heated enclosure to dry your filament to your Box Turtle? We have those here! Starting 10/1/2025 these also include Injection Molded Trays for our customers at no cost!

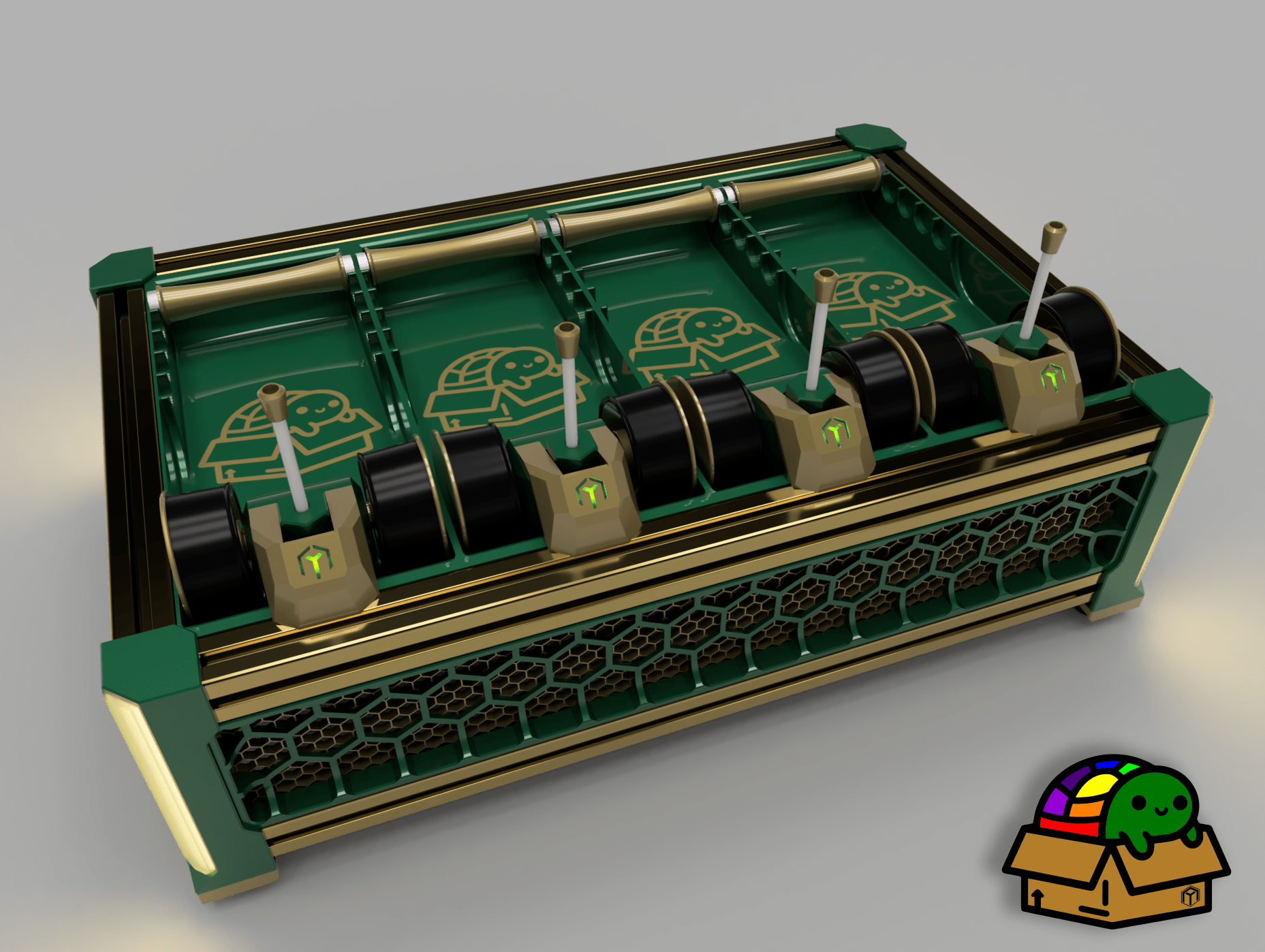

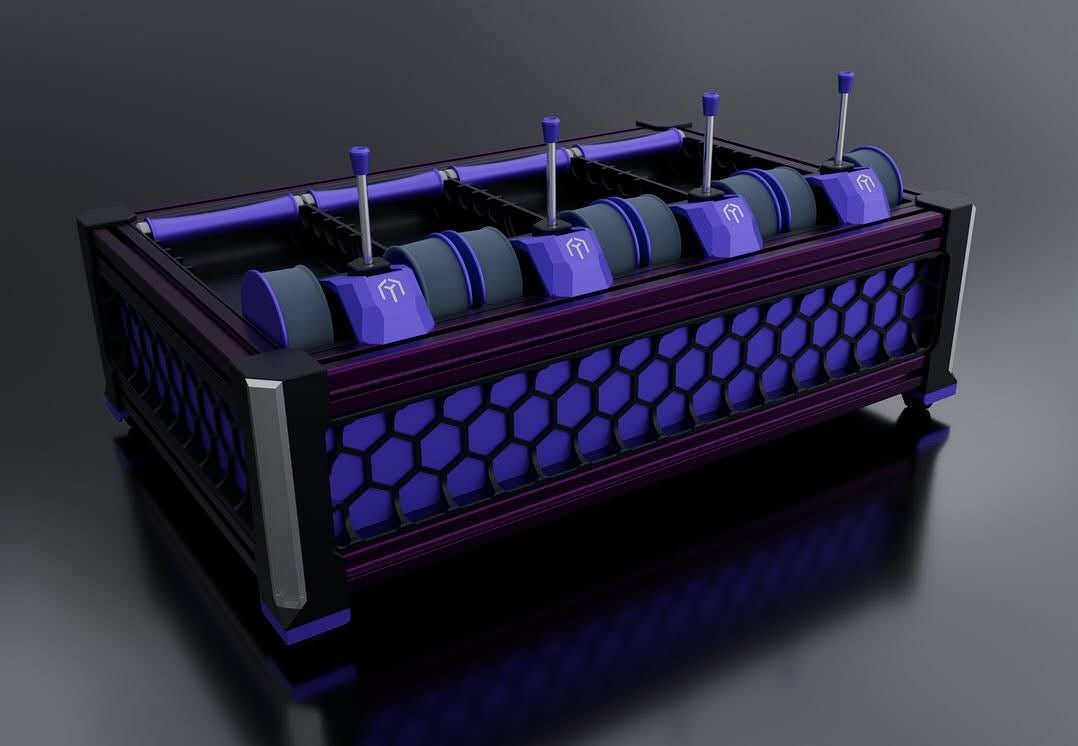

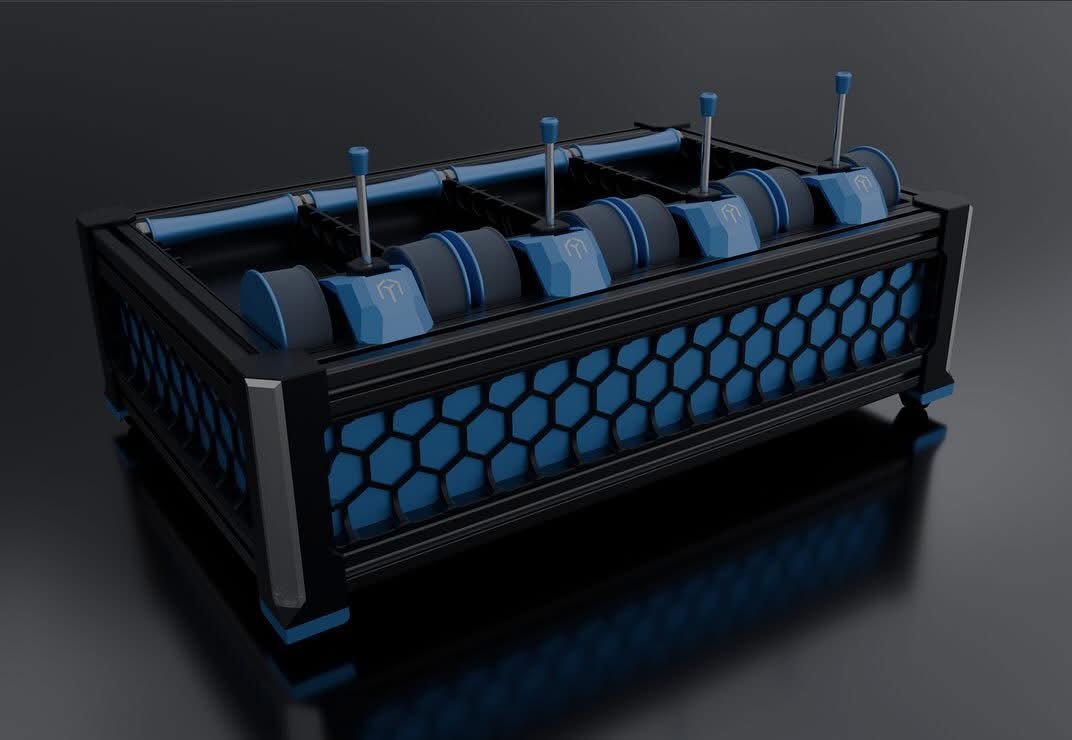

Have a Klipper Printer and want an "AMS" like solution for multi-color (or material) printing? Meet Box Turtle, an open source AMS-style filament changer for Klipper.

Get ready for a fun project that'll take your printer to the next level!

Every purchase of this kit from West3D benefits the designer, Armored Turtle to support their development.

The LDO BoxTurtle (LBT) is based on BoxTurtle original design with some useful added features and extras. Main features:

- Smooth and powerful LDO pancake motors

- Comes with AFC-Lite board, support both CAN and USB

- Premium Anodized Extrusions for frame

- Omron D2HW switch for filament sensor

- Pre-crimped cables included (except the cable you use between the Box Turtle and the machine)

- Filametrix parts kit included

- Turtle Neck Buffer (TN) parts kit included

- Hard Mount Hardware included

- MJF PA12 Gears for re-spooler also included

- Kit includes LDO tires and feet, eliminating the need for printing these

Please note: this includes all bill of material items except for Printed Parts! You can find those on the GitHub linked below.

From the official GitHub:

Find the full BOM here: https://www.armoredturtle.xyz/docs/boxturtle/bom.html

BoxTurtle is exactly what it appears to be — an open source AMS style filament changer for Klipper machines. BoxTurtle requires the AFC-Klipper Add-On (found here). The goal of BoxTurtle is to deliver a user experience as close to an AMS as possible in vanilla Klipper. i.e. an "AMS" for any klipperized printer regardless of form factor but VORON Design printers in particular.

If you appreciate the work we are doing, you can support us here.

BoxTurtle is an automated, lane-based filament changing system, also known by some as a "Type B MMU." Each lane is equipped with its own dedicated motor that moves filament to and from the tool head independently, eliminating the need for a selector cart or servos. Synchronization between the lane motor and the tool head occurs when the filament triggers a sensor (such as FilaTector) that is located in or near the tool head.

To accommodate any differences in rotation distance between the extruder in the tool head and the lane motors, BoxTurtle uses a toolhead buffer, such as the Belay by Annex Engineering or the TurtleNeck by ArmoredTurtle. This system is "bufferless," meaning no filament boxes (no spaghetti boxes) are required, similar to the AMS. Each lane features an independent respooler equipped with a brushed motor, which helps rewind the spool and assists the lane motor in feeding the filament smoothly. This prevents issues like spool tangling or "bucking."

For precise PWM control of the brushed motors, BoxTurtle relies on a custom MCU, AFC-lite, developed by Isik's Tech @xbst While the system currently supports BTT MMB CAN, this is a temporary solution to facilitate broader testing and will not be a permanent feature.