Want a hot end that will keep up? This is an excellent option, with flow rates more than double a traditional high flow hot end.

Offered in both Air and Water Cooled (great for higher temp applications!) this is one of the premier hot ends on the market!

▉Experiment and model links:

▉Description:

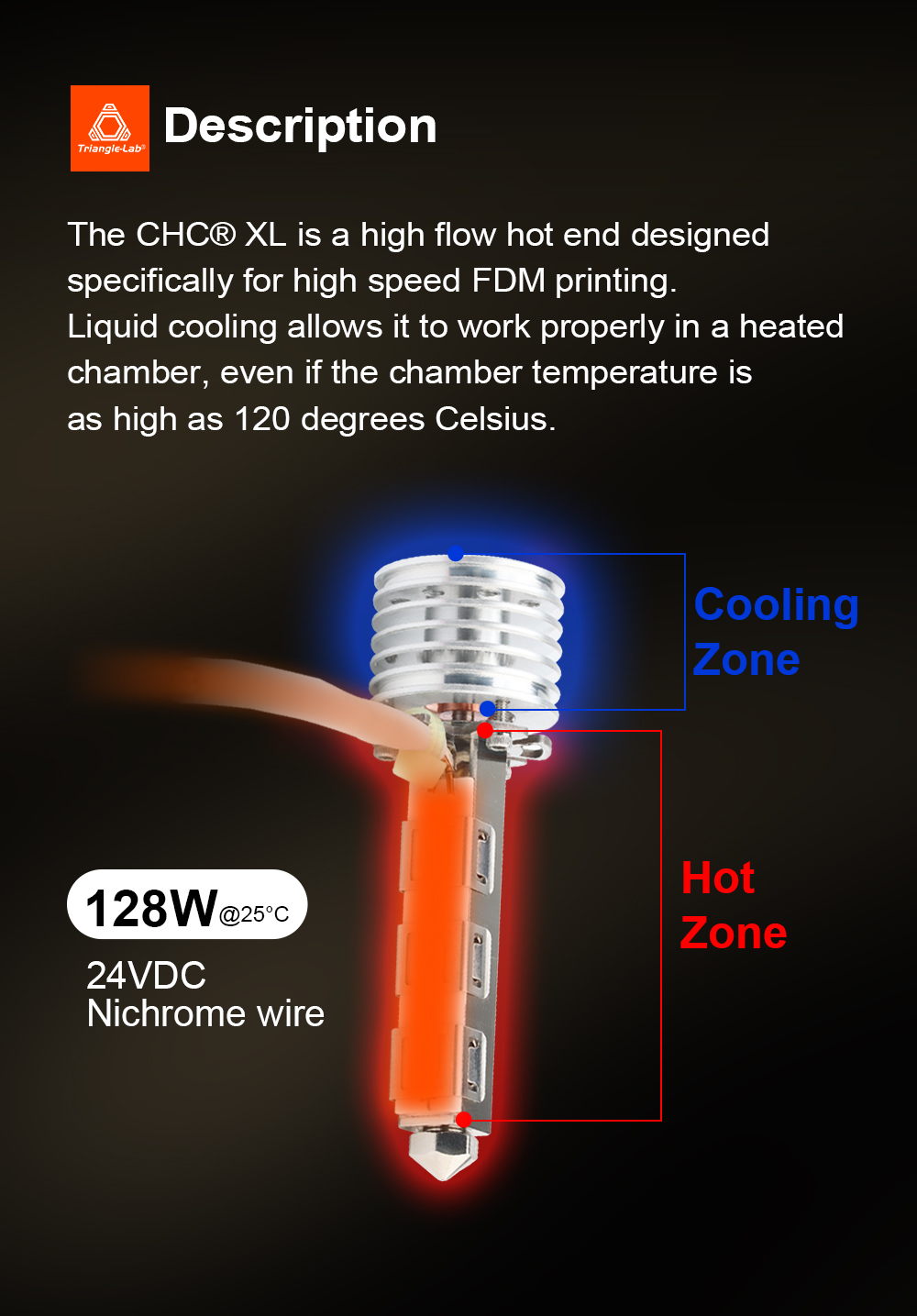

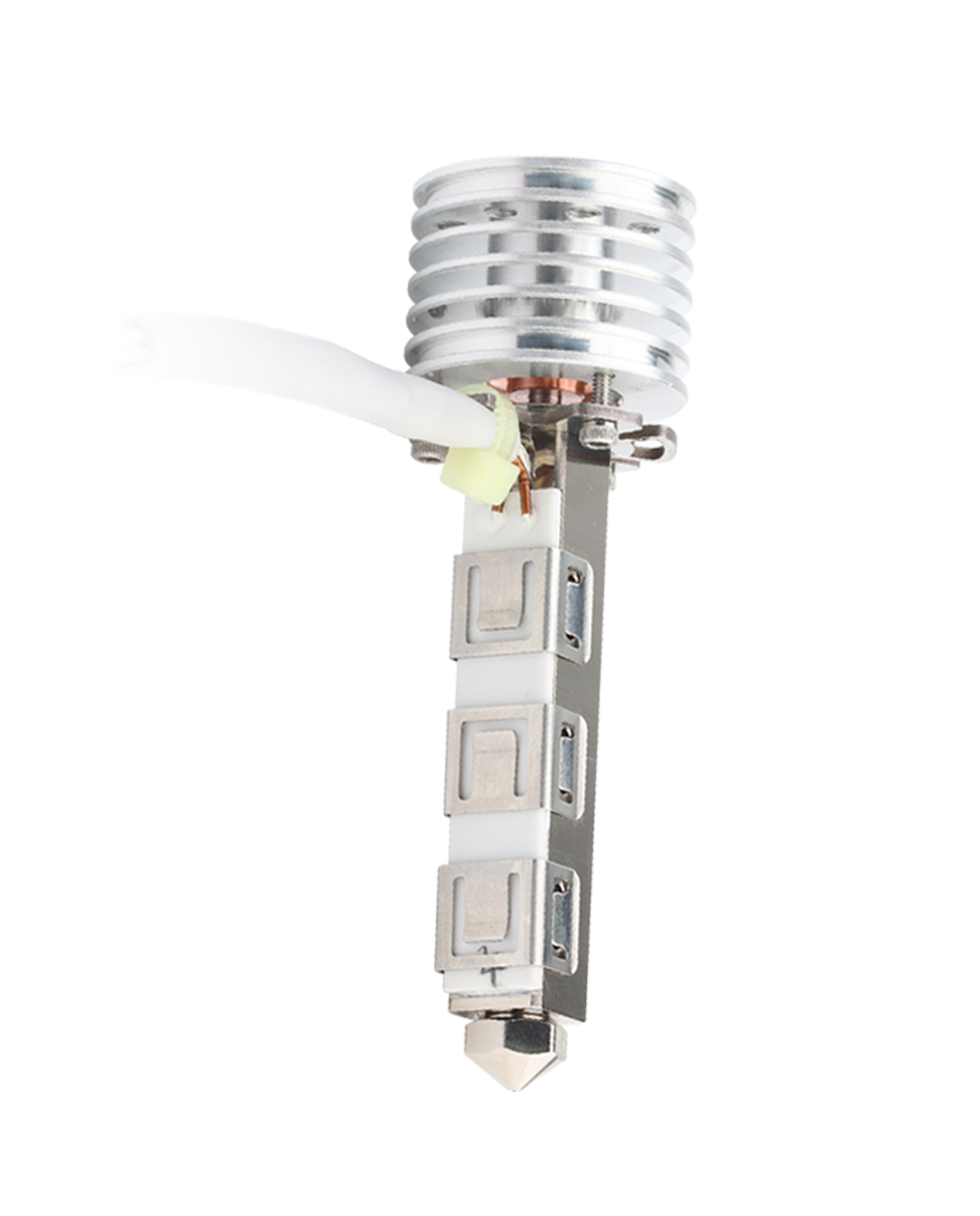

The CHC® XL is a high flow hot end designed specifically for high speed FDM printing. It has a lightweight design with ceramic heating elements to reduce dead weight at high speeds. It is compact and ruggedized to reduce your cost of operation.

▉Highlights:

-Compact form factor and light weight.

-High flow rate to meet the requirements of high-speed printing.

-Air-cooled and water-cooled options, even if your heater chamber is up to 120 (water cooled) degrees it can still print normally.

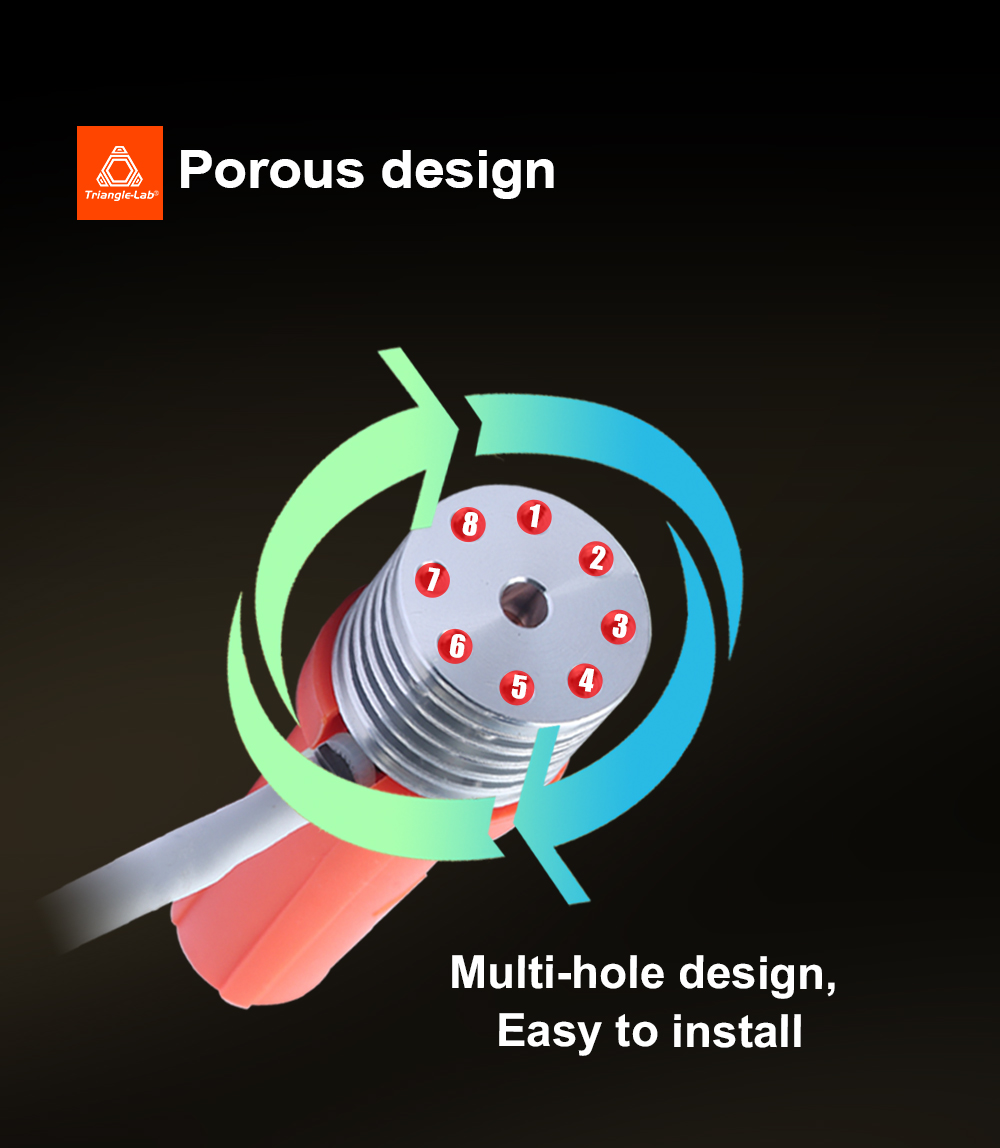

-Thanks to the patented multiple thermal break design, the cold end of the heat breaker can be kept at a lower temperature, which reduces the requirements for environment and heat dissipation, and also reduces the occurrence of thermal creep and improves the success rate of printing.

-Embedded temperature sensor for more accurate temperature control.

-Rugged, patented monolithic construction prevents damage to the thin-walled throat from nozzle changes or accidental collisions.

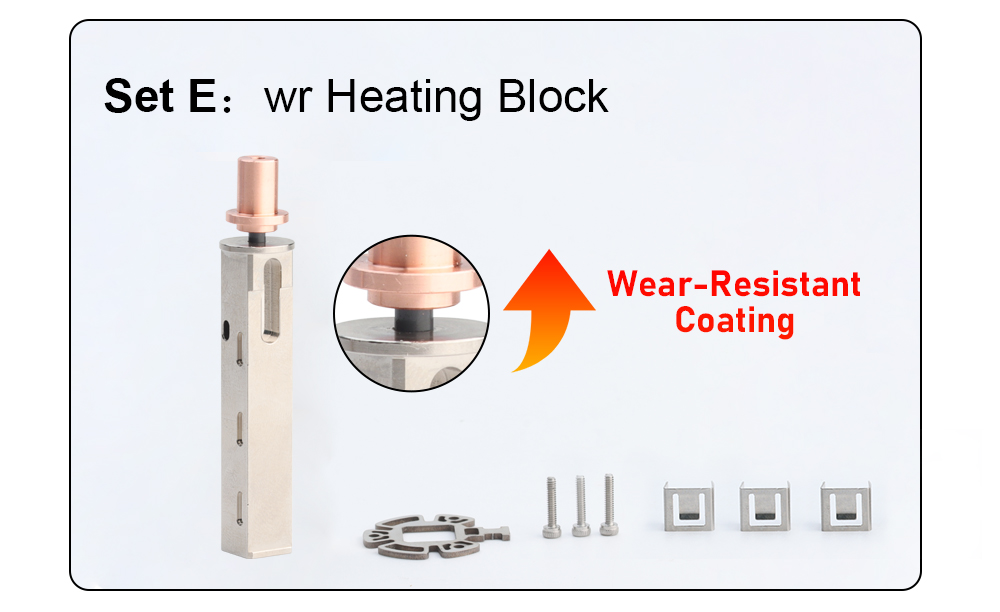

-Optional ceramic wear-resistant coated transition zone increases the life of the print wear filament by up to five times.

-Compatible with V6 style nozzles and can also be fitted with a melting zone extender to increase flow even further.

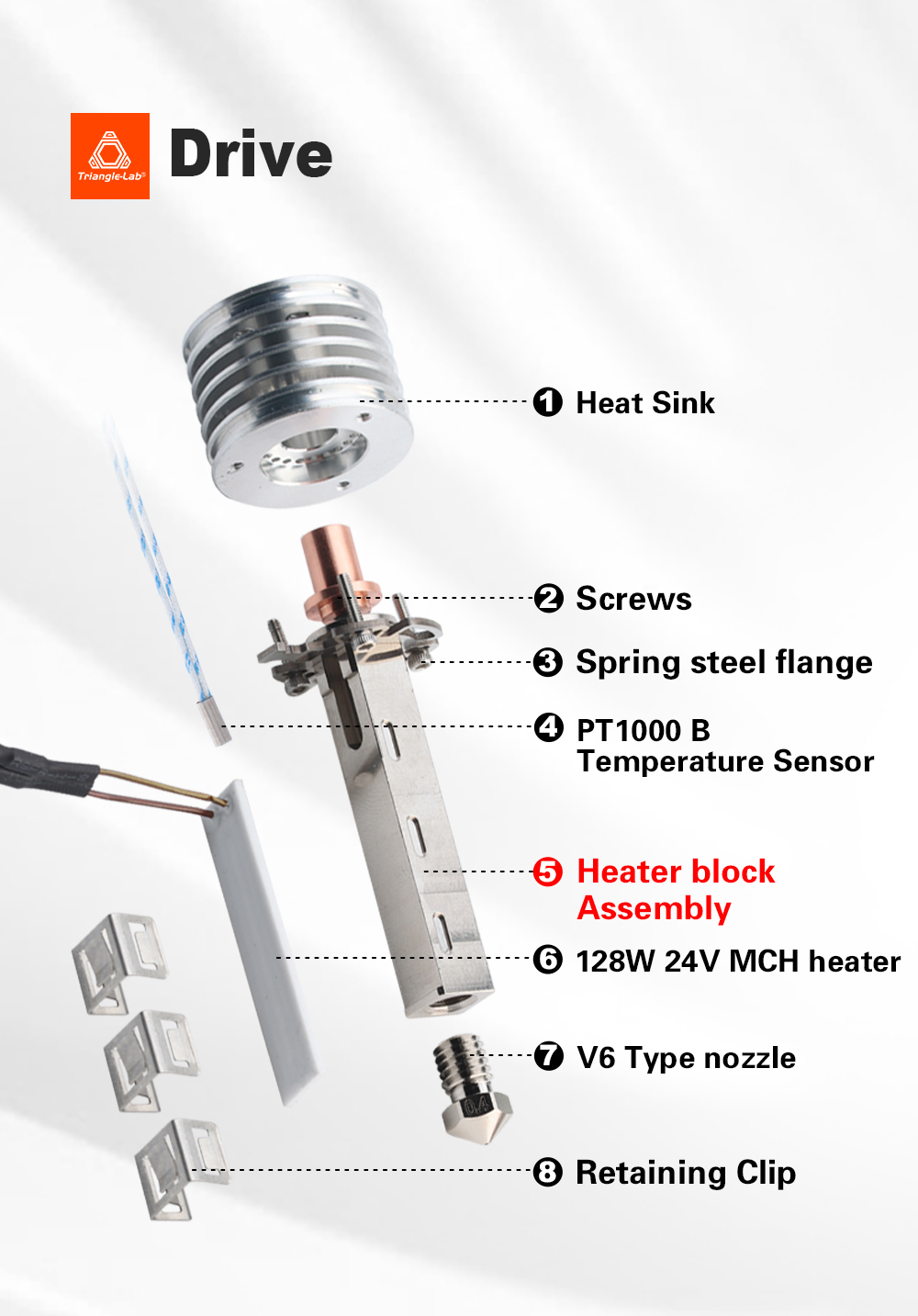

-Easy to maintain, Replacement of heating elements and temperature sensors is a breeze.

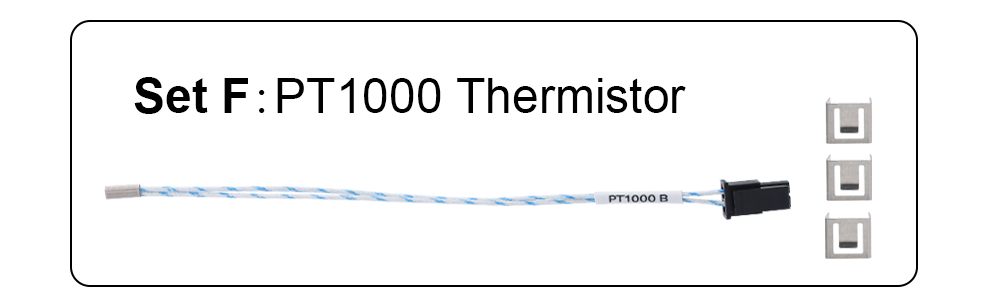

-Multiple temperature sensor options.

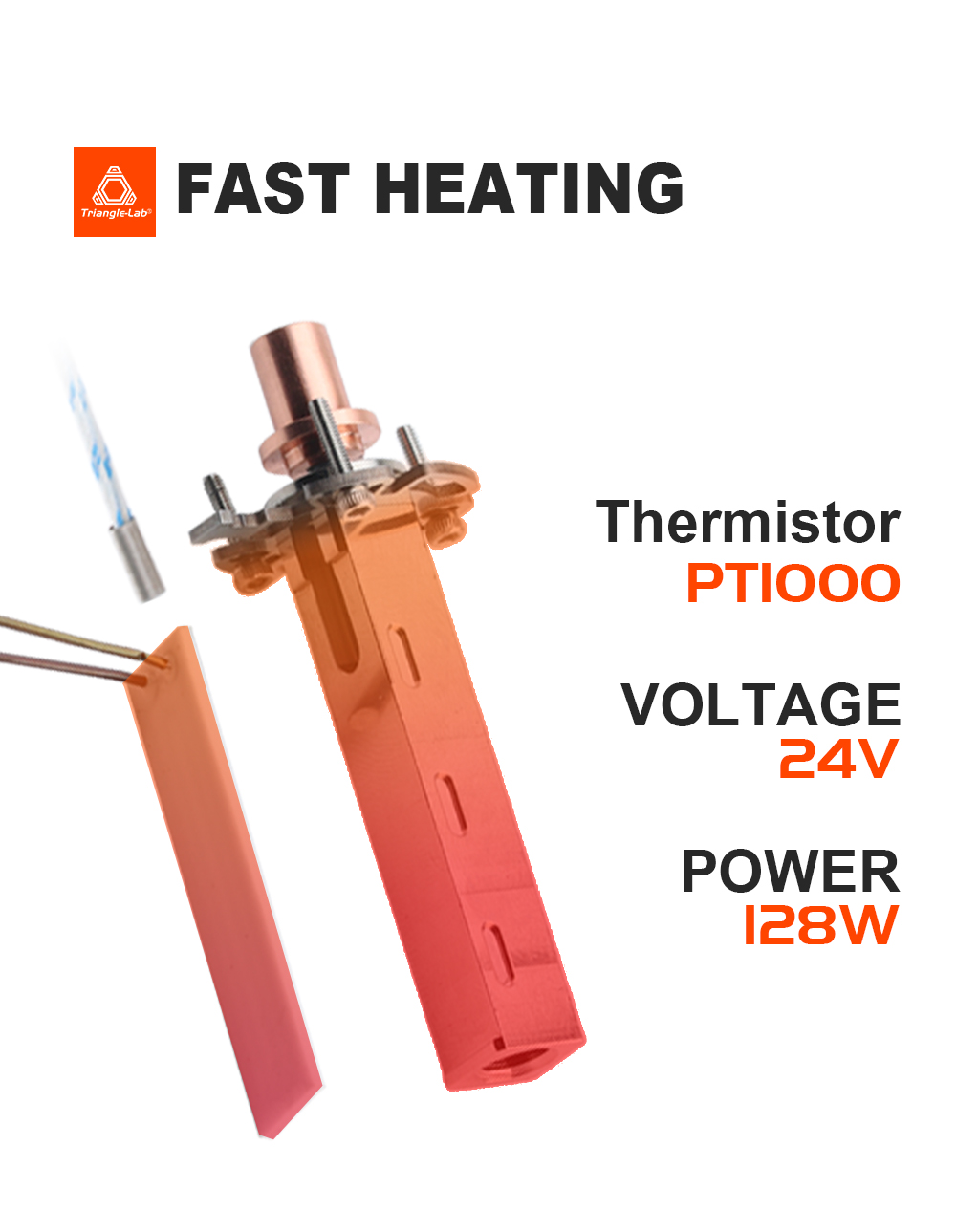

-MCH ceramic heating elements with low temperature resistance coefficient will not lose too much power even after the temperature rises.

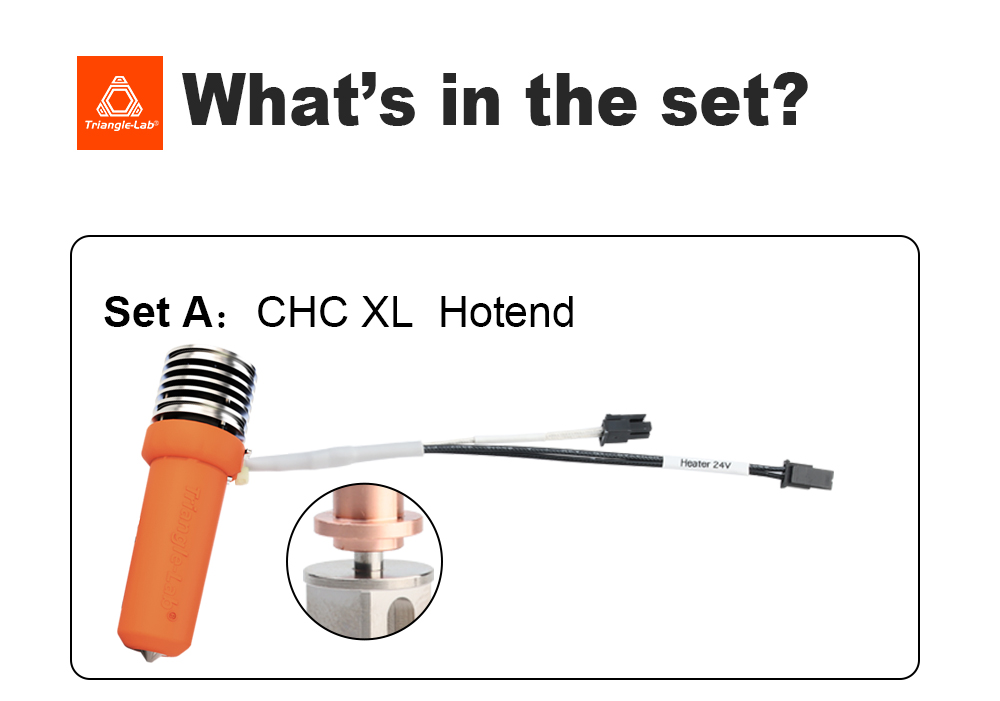

▉What's in the set?

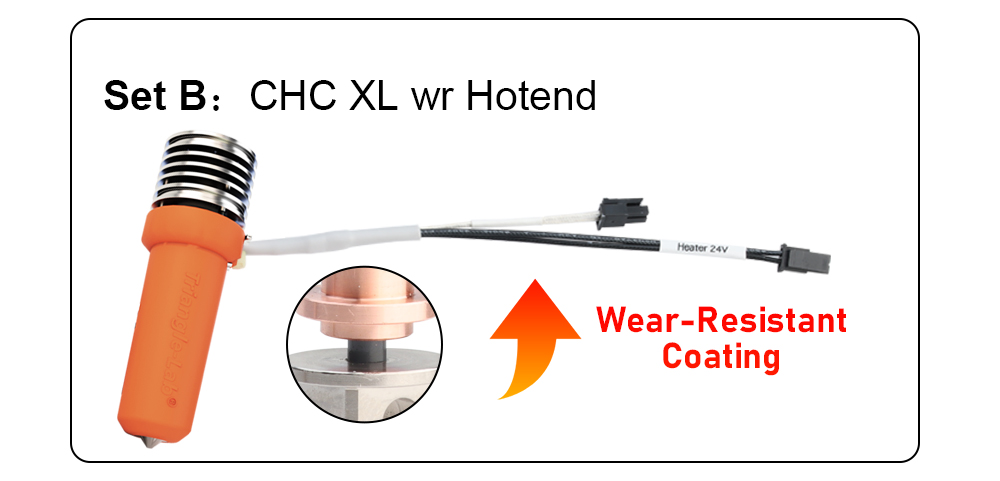

-CHC XL WR (Wear Resistant) Hotend either Air or Water Cooled (your selection)

-Heatsink

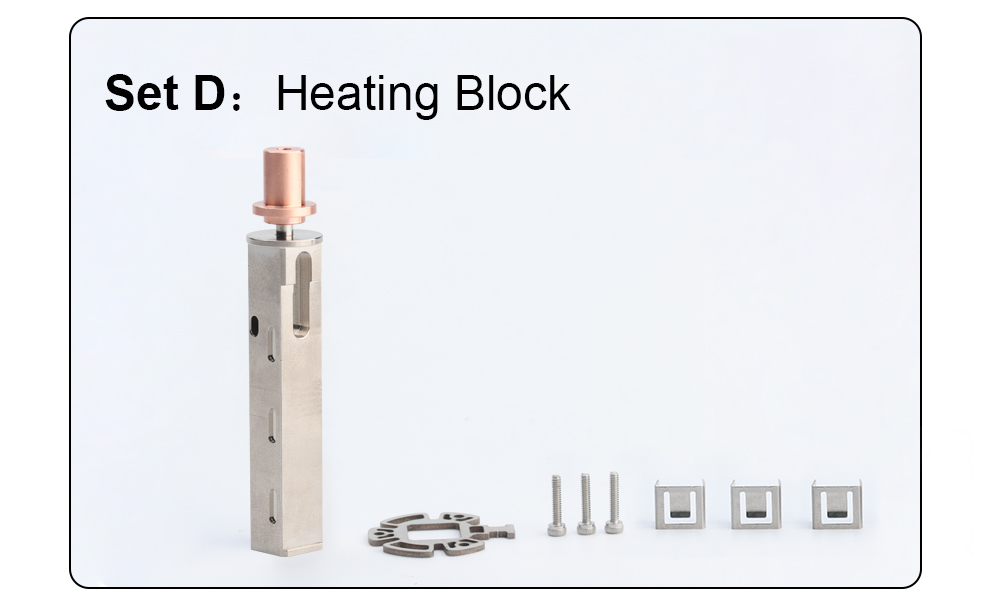

-WR Heating Block

-PT1000 Thermistor

-Ceramic heating element

-Socks X2

▉Experiment and model links:

▉Print Test

Hotend: CHC® XL hotend from Triangle-lab®

Experimental Platform: Modified CR-10 with klipper firmware Figure 5

Mounting method: Evantis 5015(S) Toolhead Figure 6

Slicing software: PrusaSlicer 2.8.0

Model: Flow Rate Test Geometry BY E3- online as in Figure 1

Nozzle type: V6 style Brass

Parameter setting: Vase mode

Extrusion multiplier: Adjust to the appropriate value according to the width of extrusion

There was no retraction during the whole process

The criteria for determining unacceptable cases are illustrated in Figures 2 and Figures 3.

▉Print Test

CHC® XL hotend with V6 style brass nozzle

CHC® XL hotend with Volcano style brass nozzle Plus MZE

、

、