Description

From our friends at ProtoPasta

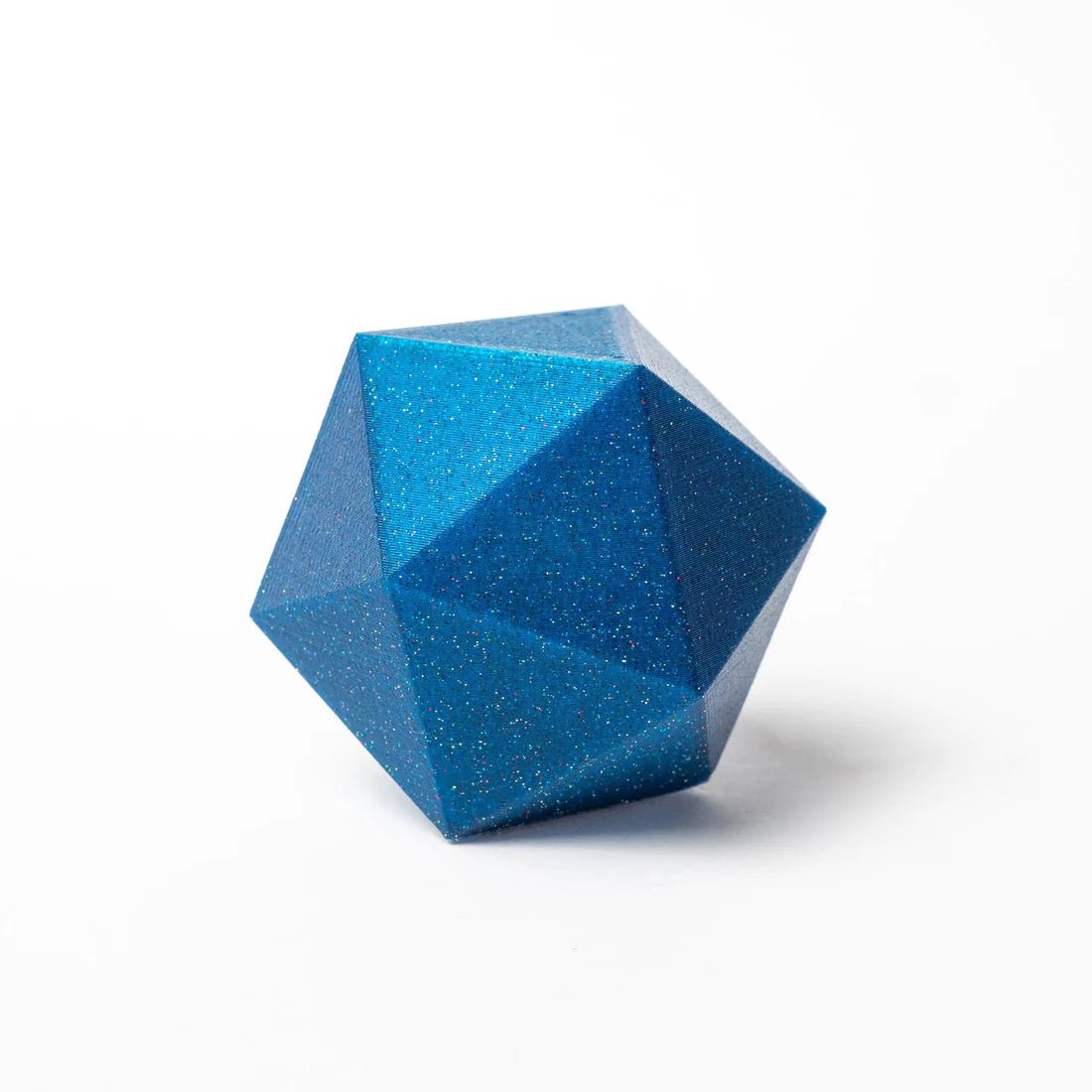

Designed by Protopasta Filament-making Workshop attendee Ben Nickles and voted "favorite " by the attendees, I introduce to you Blue Wonder Rainbow Glitter HTPLA . On July 21st, our workshop attendees got first access to our new gold and multi-color glitter flake concentrate during our first ever filament-making workshop! Ben seized the day in designing this one-of-a-kind metallic blue PLA filament and everyone loved it so much that we agreed to release it, commemorating the experience. Other than being an original creation, you might wonder how this blue is different than others? Well, it's translucent and has big multi-color flecks!

Wonder what happens in a filament-making workshop? This!

For this improved the performance, your prints should be baked in an oven until you see a change from translucent to opaque with reduced gloss. This visual change indicating the improved performance! We've seen the change take place in 5-10 minutes on thin walled parts but can take an hour or more. We've had good luck in a quality, at home convection oven at 110C (225F). Parts will get very "floppy" before becoming more firm, so please leave supports on your parts or support them and bake them on a flat, non-radiating surface (like glass, ceramic, or composite).

- Available in 1.75 & 2.85 (3) mm diameter on a 500g diameter recyclable cardboard spool

- Usable on most PLA-compatible printers, such as Lulzbot, Makerbot, FlashForge, Dremel, Ultimaker, Printrbot, and more!

No abrasive fillers so expect normal wear with standard nozzles.

In our experience, good results were achieved using standard PLA parameters ranging from 195-225C nozzle with standard build surface preparation (blue tape, glue stick, or BuildTak). No heated bed required but up to 60C is okay. Beware, if the bed temperature is too high, your part base could actually heat treat while printing, increasing warping and decreasing adhesion. Some shrinkage will occur in the heat treating process, so dimension critical parts may need to be scaled appropriately (as much as 2.5% in our experience).