Description

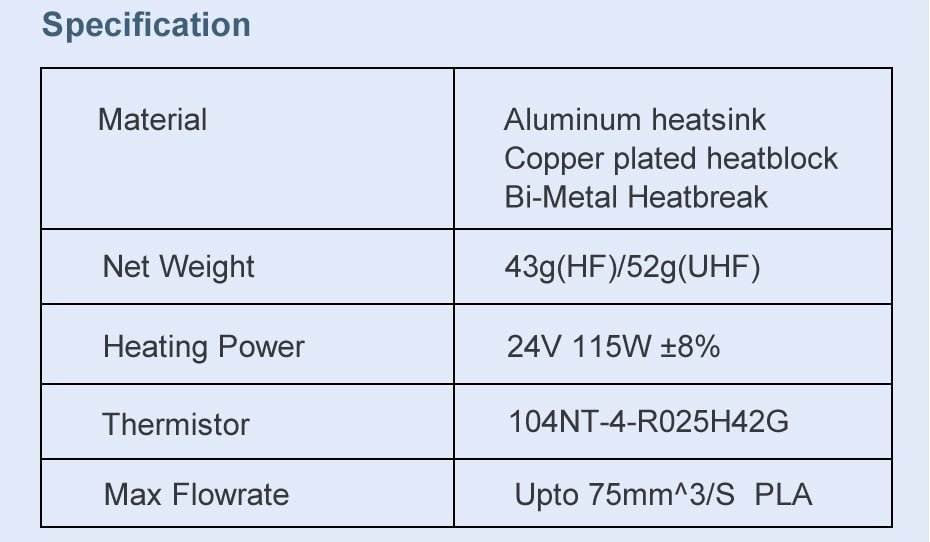

- The ceramic heating unit adopts a planar structure, which is more reliable with higher heating efficiency.

- The inlet structure of the heartbreak tube is optimized to avoid the risk of deformation and plugging.

- The material of the heartbreak tube will use titanium instead of stainless steel, which makes a better thermal insulation.

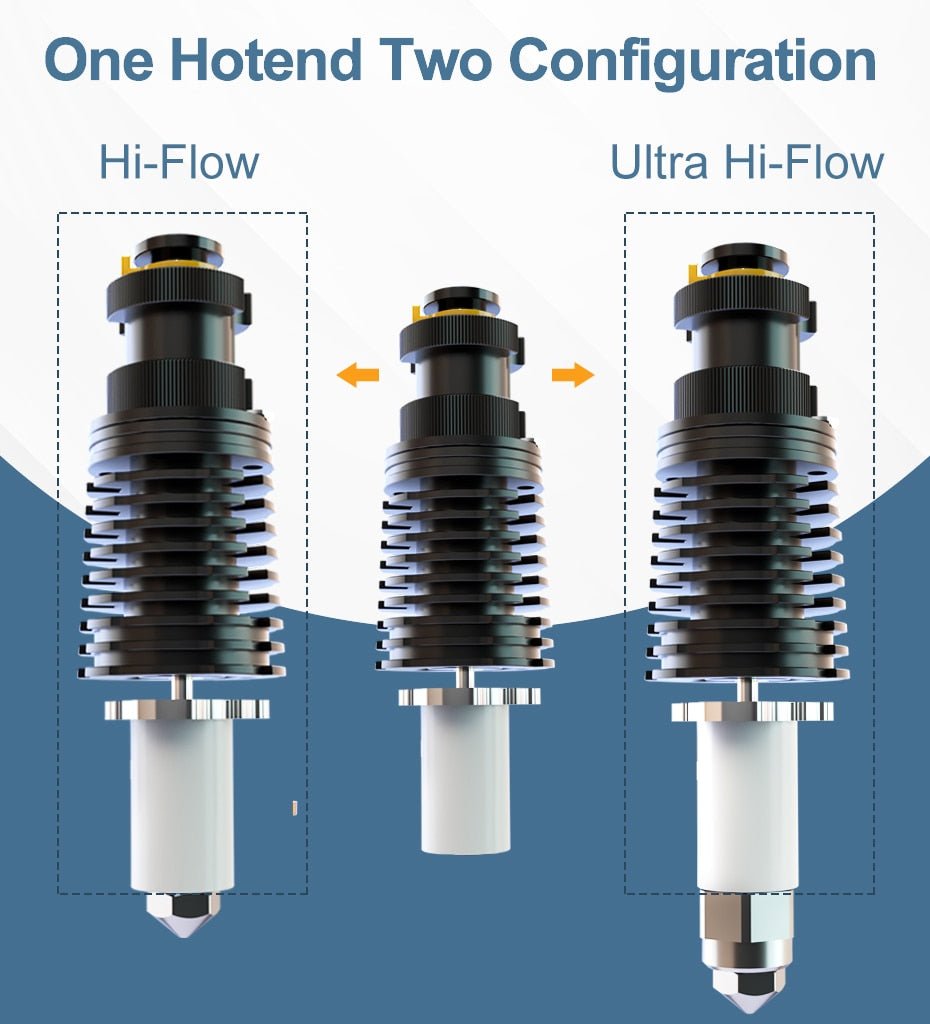

HF (high flow) variant comes with one v6 style Plated Copper .4mm Nozzle, UHF variants come with one v6 plated copper nozzle and one v6 hardened steel nozzle, an adapter nut and an extra UHF silicone sock AND all HF parts.

Rapido hotend has a unque copper alloy cylindrical melting zone wrapped in a high-powered ceramic heating element so that it has a more uniform heating section and a shorter heat transfer path. Therefore, greater flow and heating efficiency can be achieved.

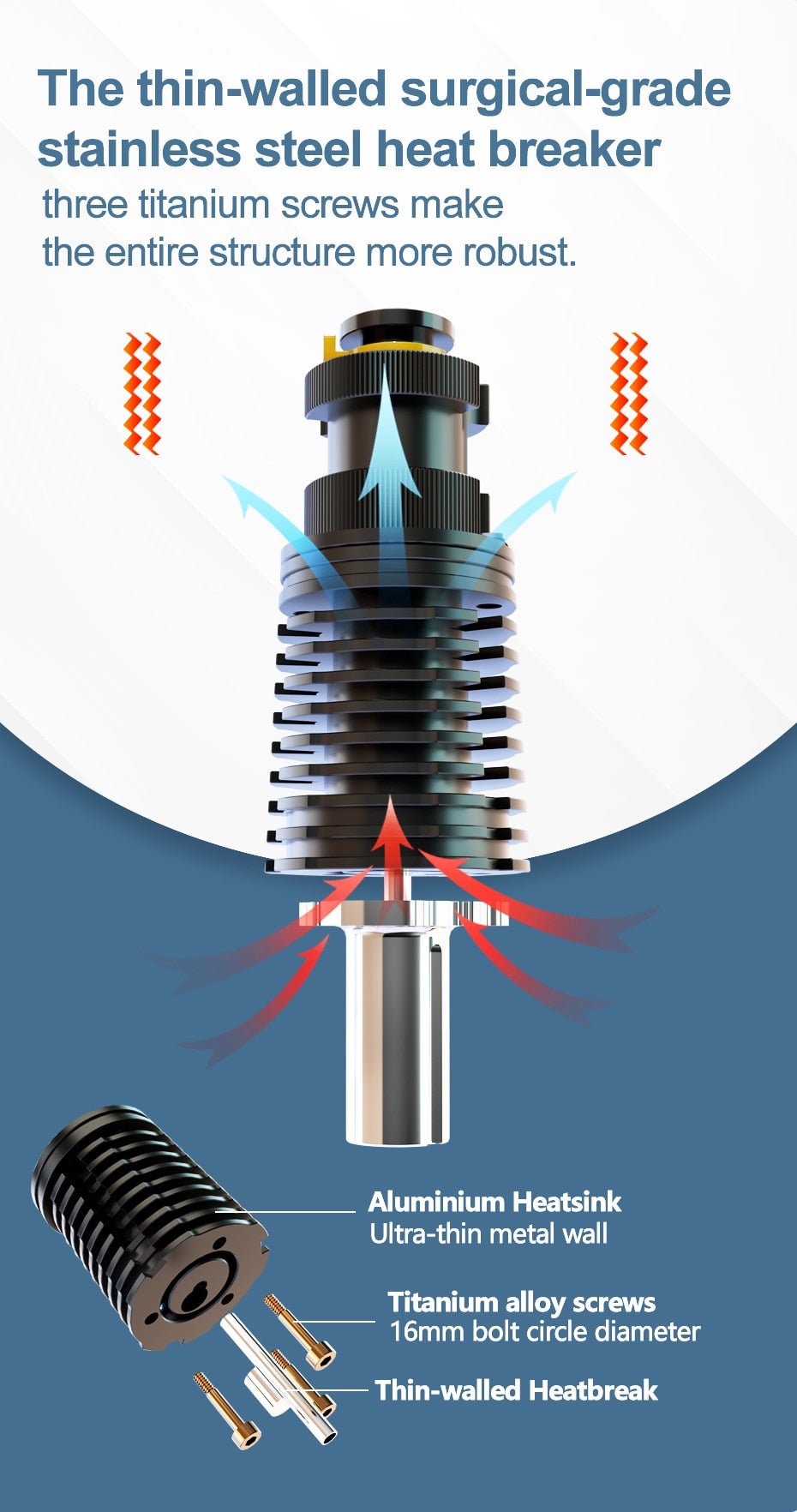

The thin-walled surgical-grade titanium heat break and three titanium screws make the entire structure more robust. With the heat sink firmly in place, the nozzle can be changed with one hand, and the heat breaker will not be easily damaged by collisions during printing.

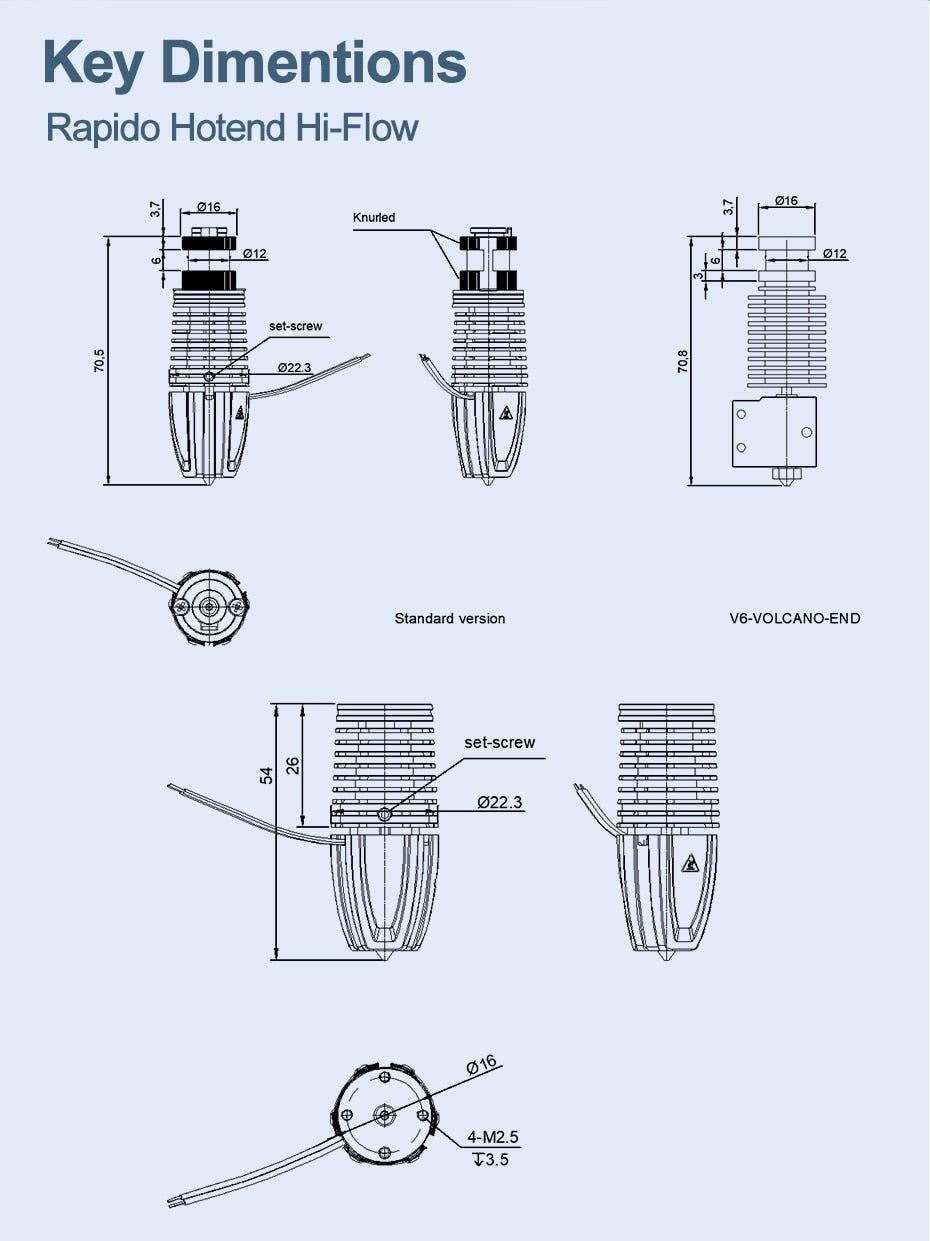

The detachable groovemount adapter allows for dual use of groove mount and screw mount. The rapido hotend has 16mm bolt circle diameter mounting screw hole same as the dragon hotend. Pre-set nozzle thread depth keeps leaks from happening again.

The rapido hotend has the same overall dimensions as the Volcano hotend with V6 or compatible nozzles installed by default. it can be used as a direct replacement for the Volcano hotend while having a higher flow rate (up to 45mm³/s) and the same extrusion accuracy than the Volcano.When the rapido hotend is fitted with a volcano nozzle and melting zone extender, it has a even higher flow rate (up to 75mm³/s) while maintaining a relatively small size and weight.