Description

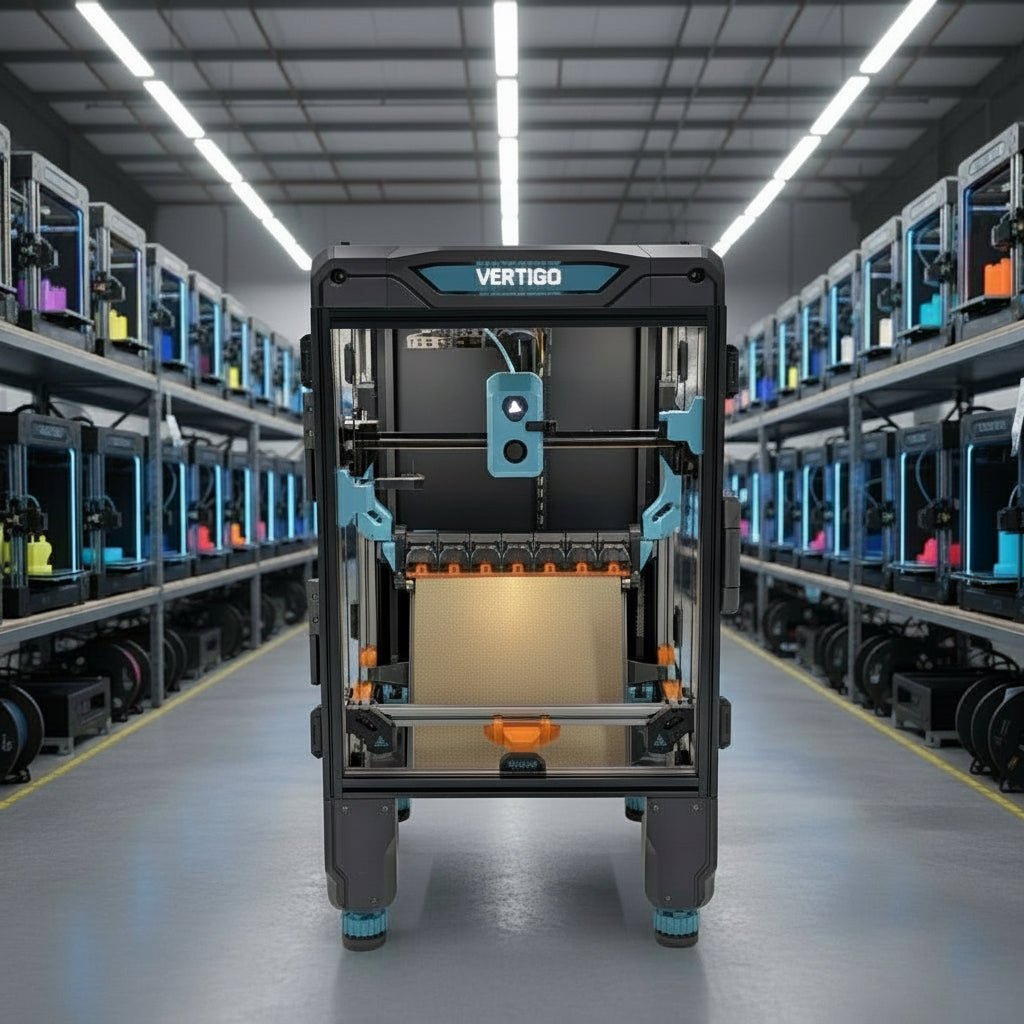

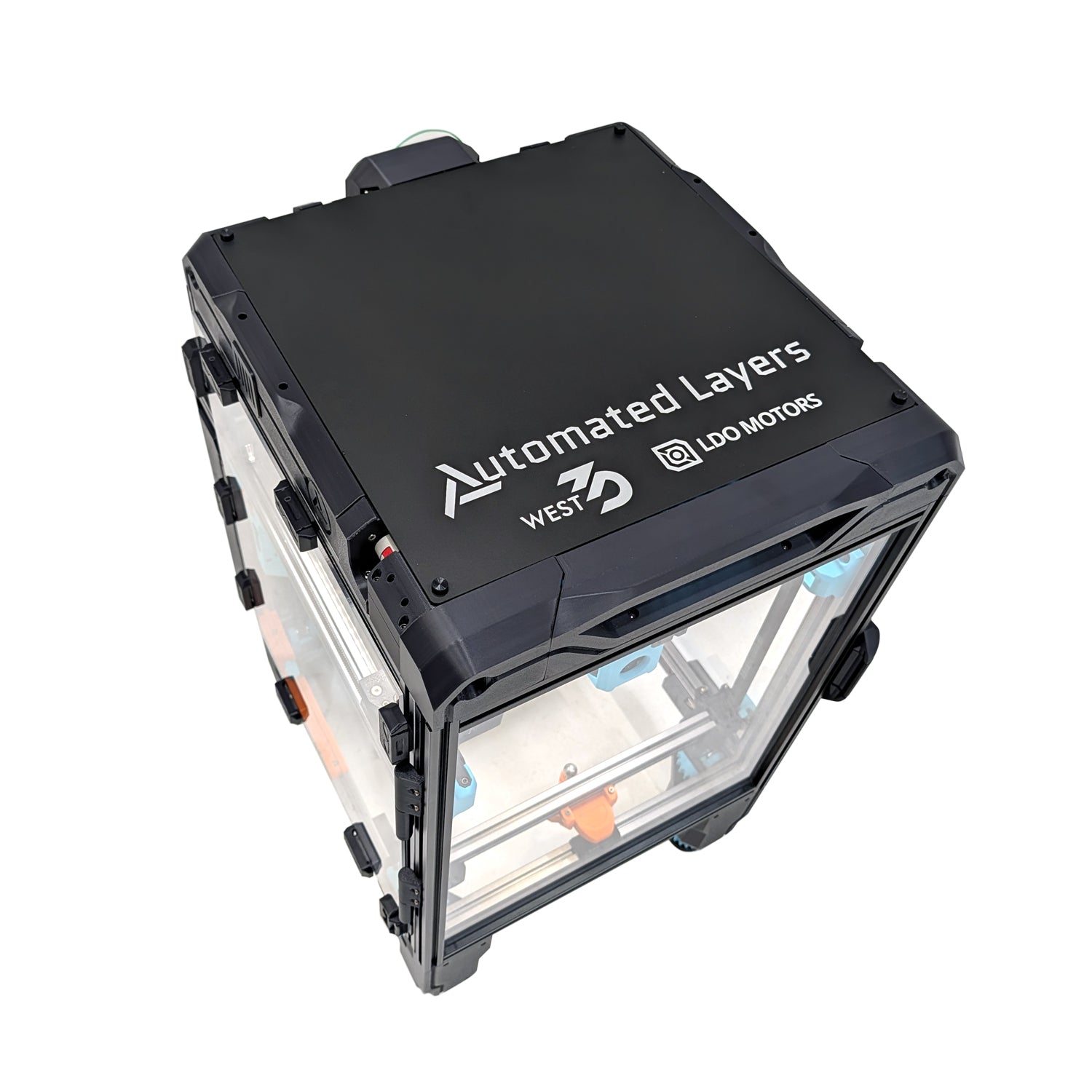

West3D is proud to be the official launch Partner with LDO Systems of the incredible Vertigo MK1 by Automated Layers.

Unlock true 24/7 production with the Vertigo MK1—the high-performance CoreXY 3D printer designed to auto-eject parts and print non-stop.

Meet the Vertigo MK1, the revolutionary 3D printer that solves the biggest bottleneck in additive manufacturing: human intervention. Engineered by Automated Layers, the Vertigo MK1 combines blistering CoreXY speeds with a proprietary auto-ejection system, making it the ultimate solution for print farms, small batch manufacturing, and enthusiasts who demand true automation.

Say goodbye to scraping beds and resetting printers. The Vertigo MK1 clears its own build plate and starts the next job automatically, designed to run continuously until the filament runs out. Paired with large 5 kg spools or an AMS/MMU, you can queue hundreds of hours worth of prints with minimal intervention.

Key Features

Revolutionary Auto-Ejection System

Think beyond a single print: the Vertigo MK1 is built for continuous production. Its signature automation sequence tips the entire heated bed 90° and uses active forced-air cooling to quickly bring the surface back to release temperature. A dual-action nylon scraper bar then glides across beneath first-layer height, lifting parts from the edge and guiding them into a collection bin while keeping the build surface and finished prints unharmed.

High-Speed CoreXY Motion

Built for speed without sacrificing quality, the Vertigo MK1 is driven by a rigid CoreXY motion system using premium components—Berserker linear rails, genuine Gates belts, and LDO’s SUPER POWER high-temperature steppers—delivering precise linear motion and high torque that keep tolerances tight and print quality rock-solid at aggressive accelerations and high speeds.

Engineering-Grade Thermal Management

Designed for demanding engineering plastics, the Vertigo MK1 uses its forced-air bed cooling system to actively heat the chamber, circulating warm air from the 400 W build plate to hold internal temperatures up to 50 °C. This stable, elevated environment drastically reduces warping and layer separation for high-performance filaments like ABS and ASA, while still letting the bed reach target temperatures quickly.

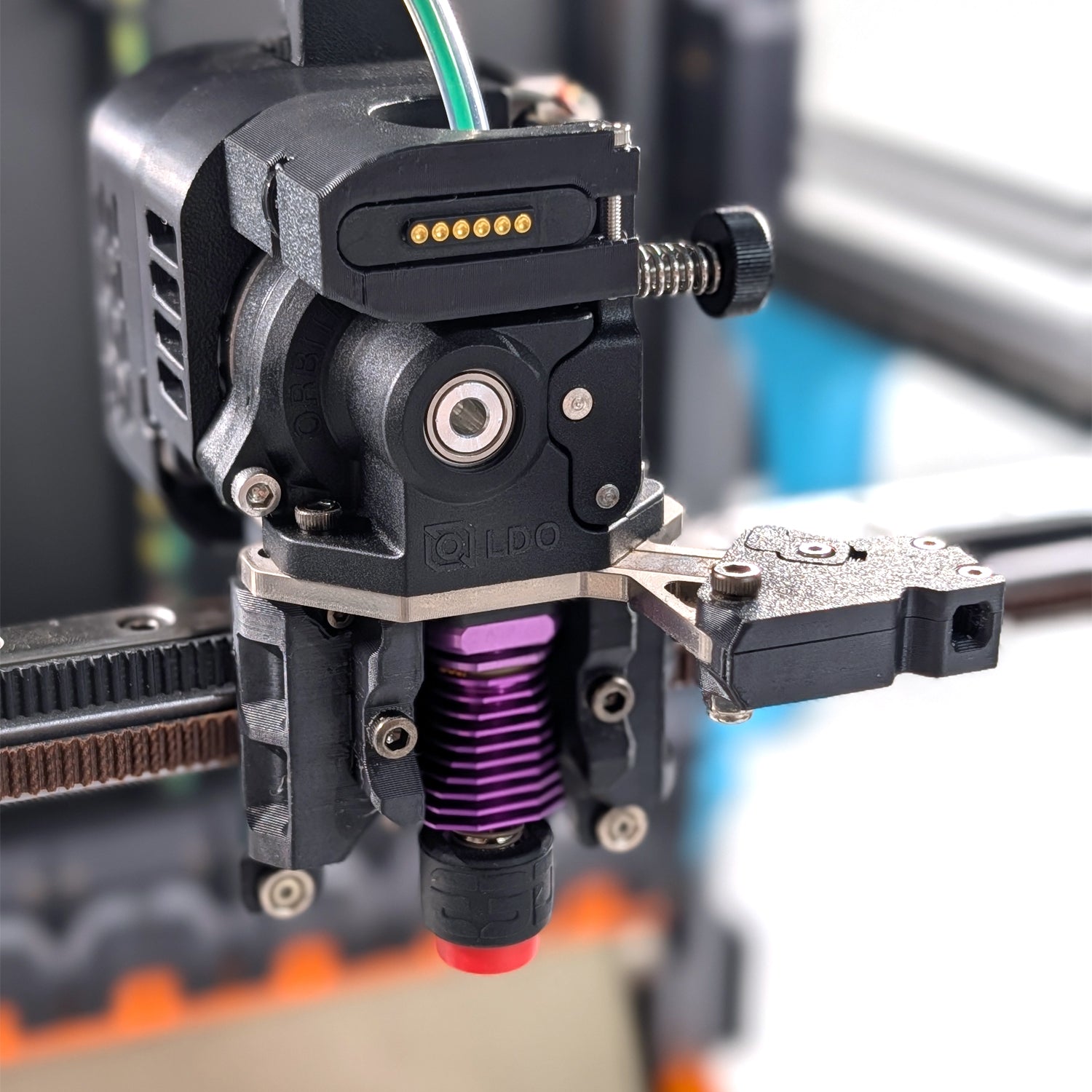

Advanced Toolhead Technology

Equipped with the Hitchcock Toolhead, the Vertigo MK1 is designed for reliability and versatility. It includes a reciprocating filament cutter to prevent jams and is compatible with multi-color printing setups, making it a flexible tool for complex projects.

Technical Specifications

|

Specification |

Detail |

|

Build Volume |

250 x 220 x 220 mm (XYZ) |

|

Motion System |

CoreXY with Linear Rails |

|

Bed Max Temp |

120°C |

|

Chamber Temp |

Active heating up to 50°C |

|

Firmware |

Klipper (with Mainsail interface) |

|

Auto-Leveling |

Automatic bed leveling & mesh compensation |

|

Automation |

90° Tilting Bed & Scraper Ejection |

Note: Printed parts are not included, but STLs can be had on Automated Layers GitHub!

Why Choose the Vertigo MK1?

-

Set It and Forget It: Queue up dozens of prints in your slicer and let the Vertigo handle the rest. Perfect for large batches or weekend-long production runs.

-

Open Source Roots: Running on Klipper firmware, the Vertigo MK1 offers deep customization and control for power users, accessible via a web interface (e.g. Mainsail / Fluidd) ) from any device.

-

Print Farm Ready: Designed specifically to reduce labor costs, a single operator can manage a fleet of Vertigo printers with minimal downtime.

Automate your workflow today with the Vertigo MK1 — the printer that turns downtime into done-time.