Recently Added

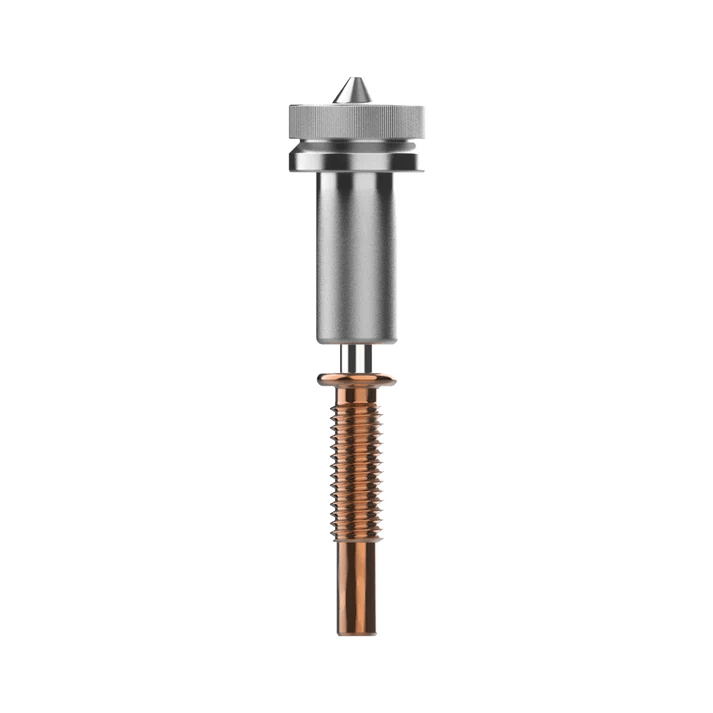

E3D

E3D Revo HTA-HF High-Flow High-Temperature Abrasive Nozzles for Revo Hotend (HF HTA)

Sale priceFrom $64.99

In stock, 37 units

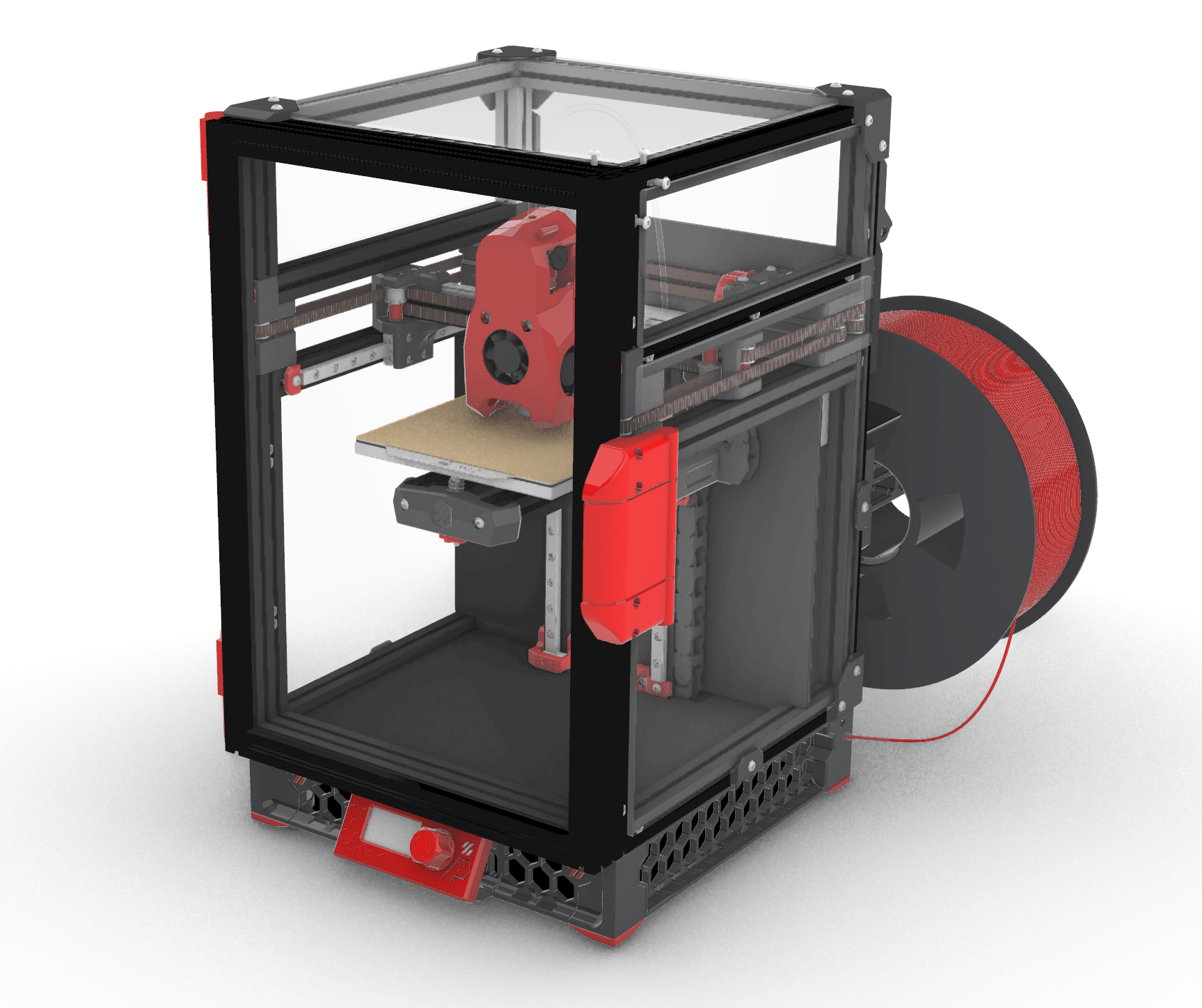

LDO Motors

Mini-Fridge (Clicky-Clack) Door Kit for Voron V0.2 (LDO) - by TheVoronModder, Presented by West3D

Sale price$34.99

In stock, 16 units

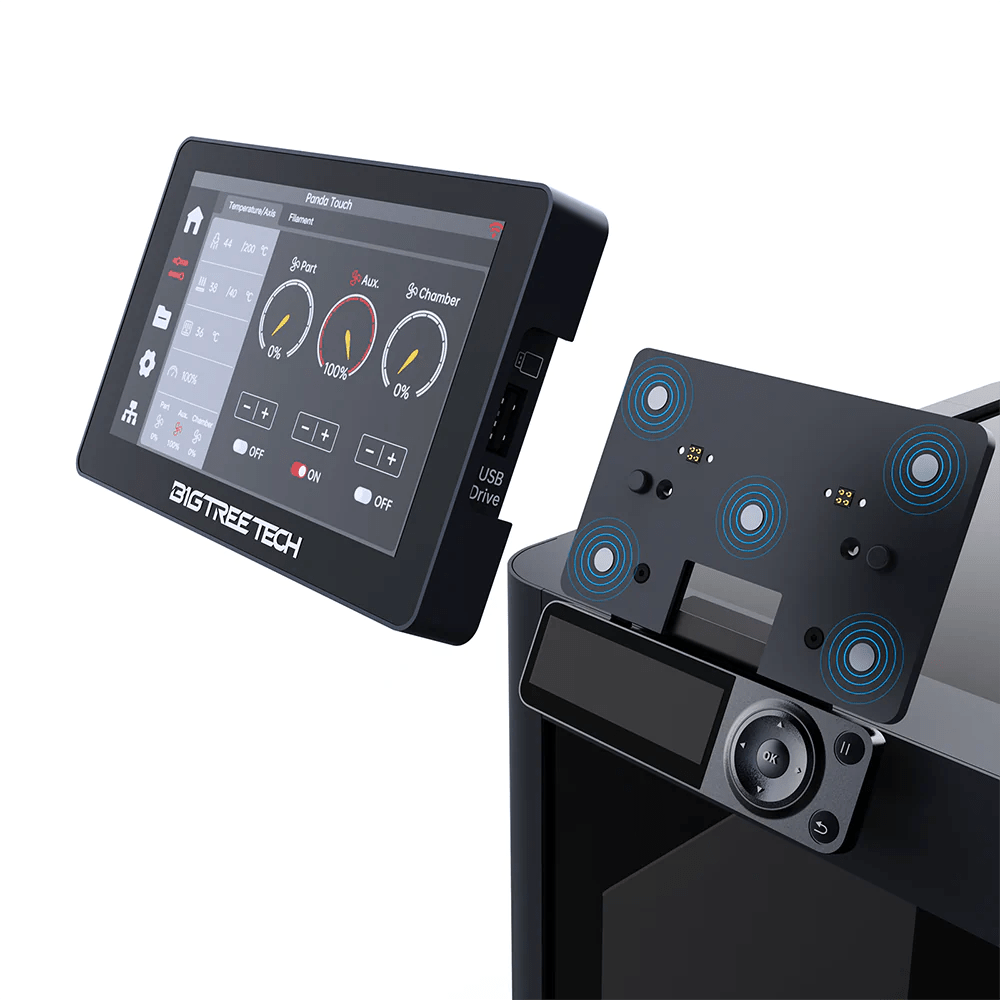

BTT

BTT Panda Touch 5-inch Touchscreen Display for Bambu Labs P1 X1 A1 P1P etc. Printers

Sale price$58.99

In stock, 46 units

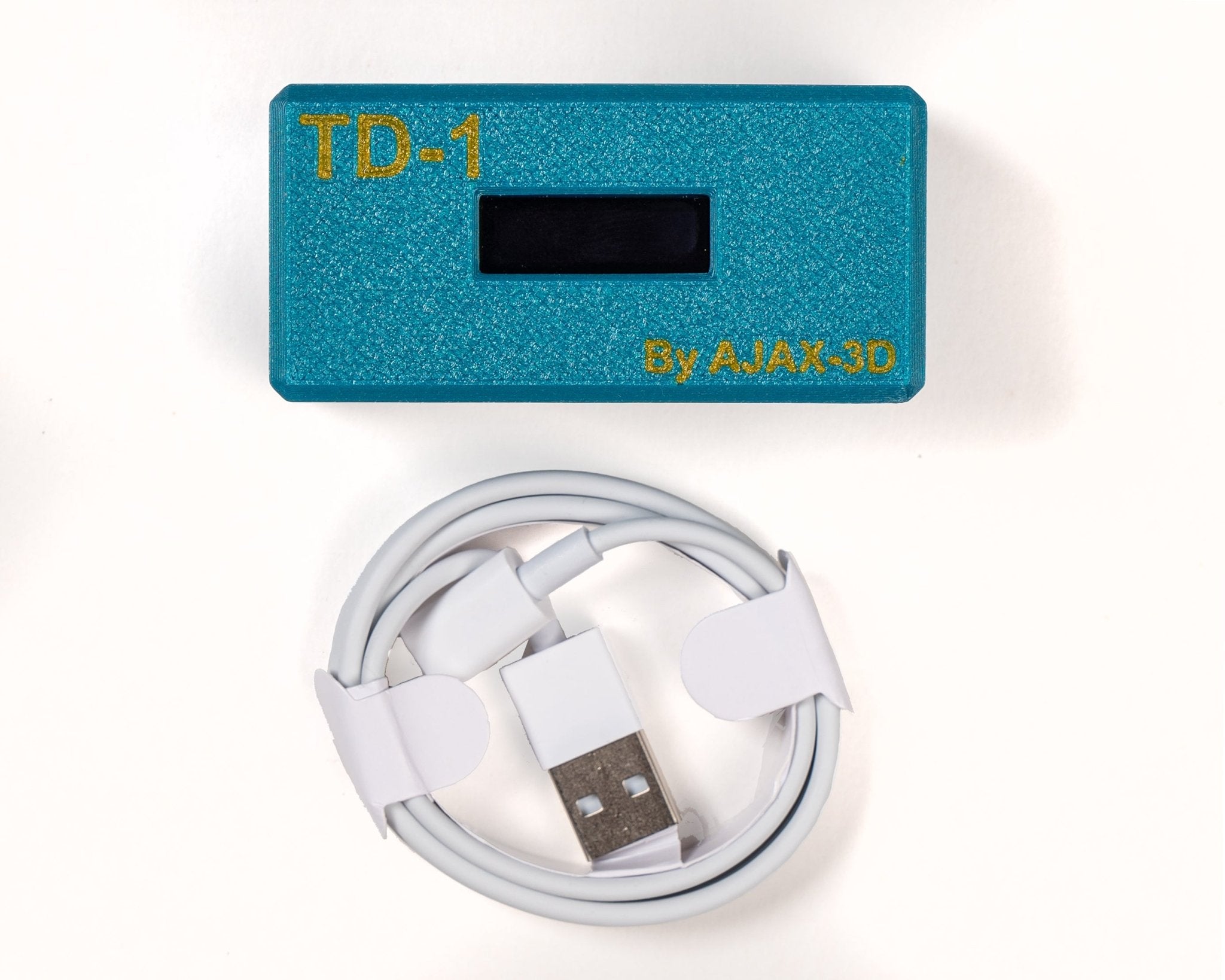

West3D 3D Printing Supplies

TD-1 Instant Filament TD (Transmissivity) Tester for HueForge (1.75mm Filament) by AJAX

Sale priceFrom $39.99

Sold out

E3D

E3D Revo Hot End for Creality Printers (such as Ender 3 / 5 / CR-10 etc. - Most Models) Builder

Sale priceFrom $59.99

In stock, 122 units

E3D

E3D Revo™ Prusa Edition RapidChange Hot End (Revo MK3 and Mini) Builder

Sale priceFrom $86.99

In stock, 60 units

E3D

E3D Revo™ Voron Edition RapidChange Hot End (Revo Voron) Builder

Sale priceFrom $86.99

In stock, 69 units